|

ME

574 PROJECT |

|

||||||||||

|

An Axisymmetric Model for Pore-Grain Boundary Separation |

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

Results: 2D |

|||||||||||

|

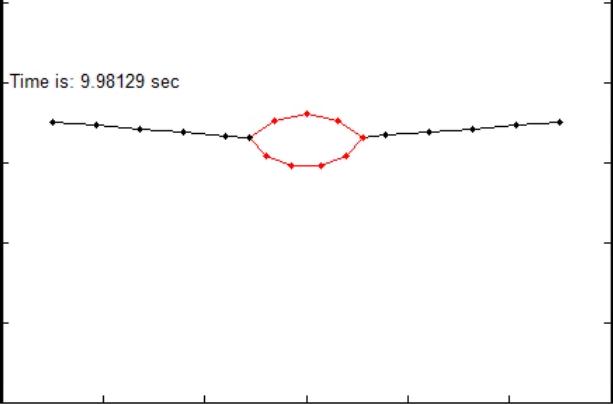

2. Grain

boundary with higher surface tension than pore surface (

) )The simulation in 2D has been carried out by using the H matrix from the class notes. Even the problem is symmetric; we still modeled the full geometry for the 2D case, which gives a clear picture of how the whole thing evolves. The focus of the 2 D simulation is to investigate the effects of different surface energy on the evolution of the grain boundary and pore surface. Other parameters for the 2D case are from the reference paper. By keep other parameters the same, only vary the surface energy term (γs is the surface energy of the pore, γB is the surface energy of the boundary). The results show 2 different sets of surface energy γs and γB. The ratio between γs and γB affects the pore shape evolution. Through the following equation:  By change the ration of γB and γs, different shapes of the pore are obtained as shown below.     Results: 3D

1. High

mobility ratio (

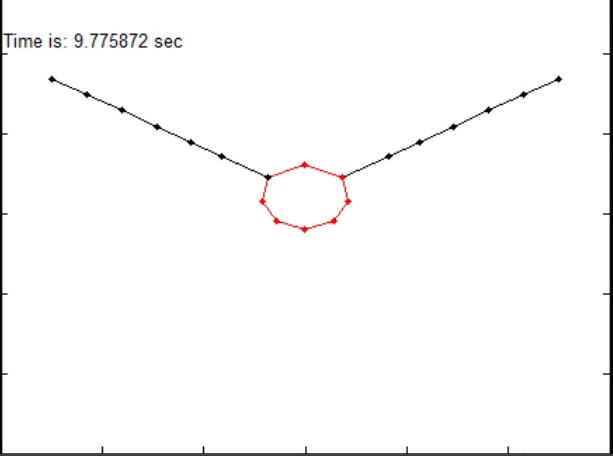

3. Neck formation

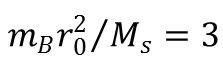

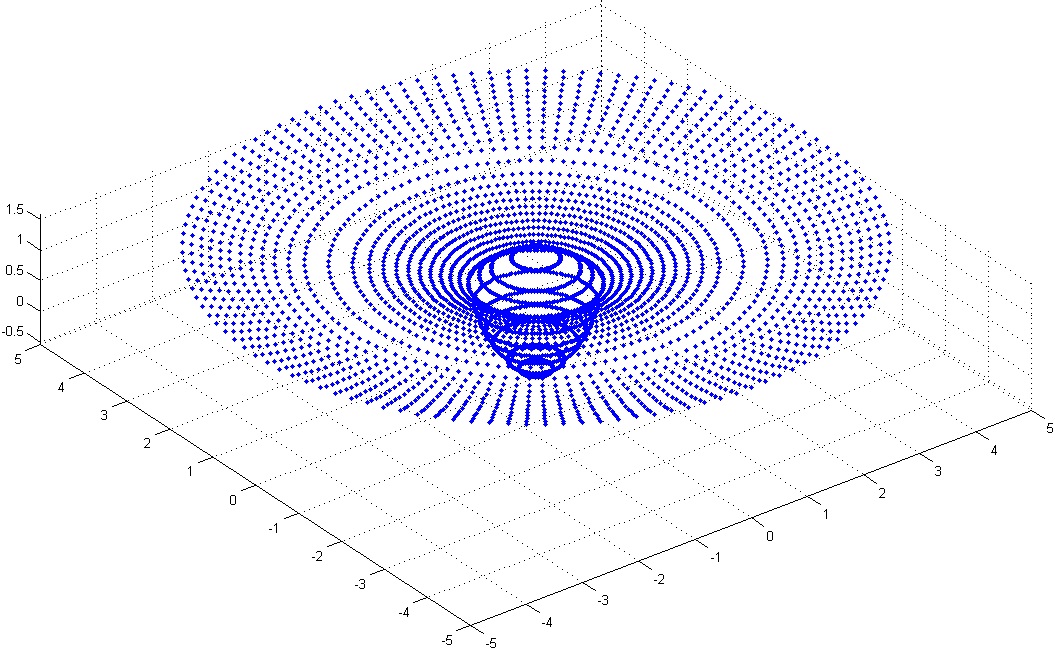

The

following 3D

pore-grain

surface motion is plotted for, |

|||||||||||

|

|

|||||||||||

|

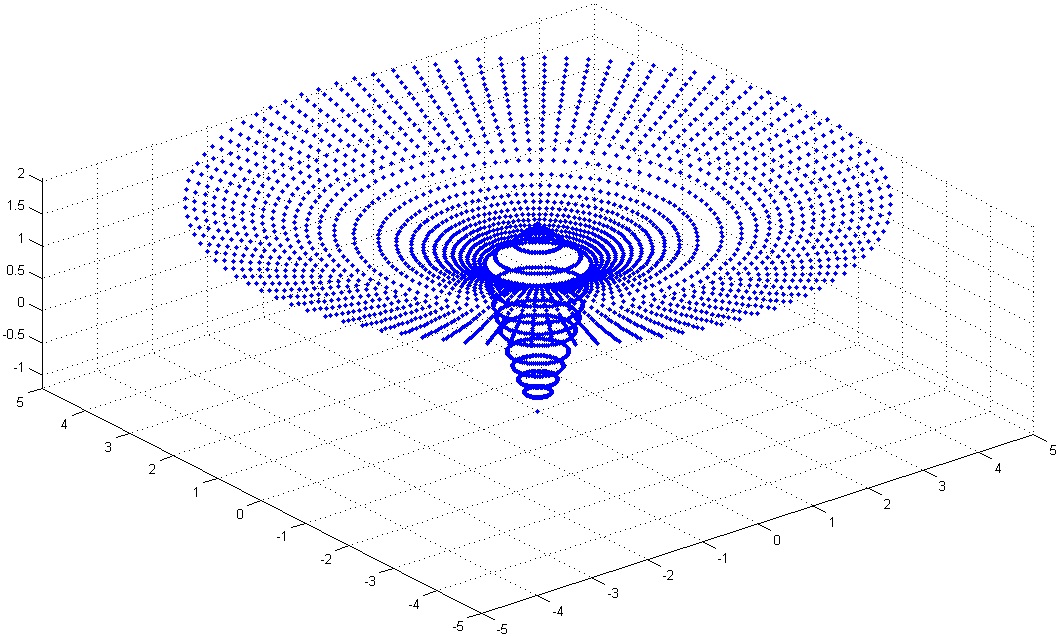

The

following 3D

pore-grain

surface motion is plotted for, indicating that the pore tends to separate from the grain boundary with the increase of the mobility ratio. |

|||||||||||

|

|||||||||||

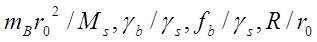

The simulation in 3D has been carried out using the dimensionless parameters:  The unit of the simulation is  . .Where r0 is the radius of the spherical pore which has the same volume with the cylindrical disk that is used to model the pore at time t=0. As the problem is axisymmetric, we model only half of the geometry. This also has the advantage of reducing the size of the global viscosity and force matrices, thus enable a more effective simulation. The simulations are focused on the effects of the mobilities on the evolution of the grain boundary and pore surface. As can be seen in the videos, by keeping all the parameters the same, only varying the mobility ratio  leads to

differences in shape change. leads to

differences in shape change. When the ratio is 1, the pore evolves in to a rounded shape, and then reaches a steady state and moves with the grain boundary. When the ratio is increased to 10, the grain boundary moves much faster. A difference between the movements of the grain boundary between two movies can be easily observed. The fast migration process of the grain boundary eventually initiates a neck form causing a pinch-off at the triple junction. Afterwards the pore will be separated from the grain boundary. This phenomenon is also captured in our simulation as illustrated in the video. In this simulation, we use 10 for the ratio between two mobilities, and also increase the force at the boundary, to speed up the migration of the grain boundary. As times go on, the formation of a neck can be easily recognized. |

|||||||||||

|

Conclusions The main aim of the present project was to present a finite element method to simulate three-dimensional (3D) axial symmetric surface motion with combined surface diffusion and grain boundary migration. To mimic the holes on the sapphire surface made by lithography, we assumed the initial condition that, at t = 0, the pore is a cylindrical disk. First, we reviewed the weak statement and used it to formulate finite element method for axisymmetric surface motion. Then, a code was developed in MATLAB to capture the evolution of both 2D and 3D pore-grain surfaces. For the 2D model, we followed ME-574 lecture notes whereas the work of Yu and Suo [1] was used to develop the 3D model. Pore-grain boundary separation was investigated to demonstrate the capability of the 2D and 3D methods along with the MATLAB programs. For the small mobility ratio, it was observed that the cylindrical pore evolved to a rounded shape quickly. After some time, it approached to a steady state shape, and moved at a constant velocity with the grain boundary. By increasing the mobility ratio, the grain boundary migrated so fast that the pore was unable to keep up. The pore separated from the grain boundary and was left inside the grain. |

|||||||||||

Future work The diffusion on the boundary grains could be taken into account in the 2D and 3D simulations to achieve a more realistic model. Also, an axisymmetric model of several pores on the moving grain boundary could be studied to see how the pores affect each other during the surface evolution. |

|||||||||||

).

).  ).

). ,

R⁄r0

=5,

,

R⁄r0

=5,

,

R⁄r0

=5,

,

R⁄r0

=5,