|

ME

574 PROJECT |

|

||||

|

An

Axisymmetric

Model for Pore-Grain Boundary Separation |

|||||

|

|

|||||

|

Introduction |

|||||

|

|

|||||

|

Introduction |

|||||

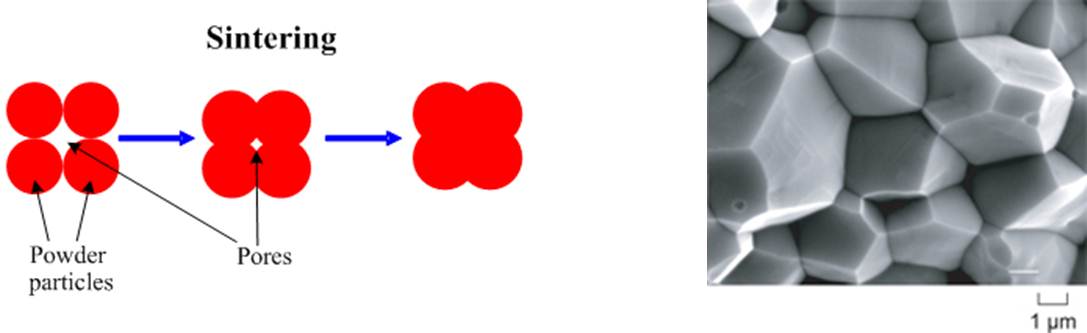

The

processing of sintering usually

starts with a porous aggregation of ceramic particles. The powder

particles are consolidated by

diffusion of atoms across the

boundaries under

high temperature below the melting point.  The pore size, shape and desity determine the quality of result products. Therefore, it is important to fine optimized sintering condition with simulation. Three atomic processes are competitive during the sintering: diffusion on grain boundaries reponsible for pore shrinkage, diffusion on pore surfaces for pore motion, and grain boundary migration for grain growth. In 1969, Brook obtained approximate pore velocity and grain boundary velocity when he assumed that pores were spherical and the separation occurs when the pore velocity was less than the grain boundary velocity. Although the model was incorrect, the separation condition showed the correct trends of pore size, grain size, surface mobility, and grain boundary mobility. In 1982, Hsueh studied about pore moving with a grain boundary migraing at a steady velocity while considering the effects of the pore shapes. This project is simulation of the transient separation processes which is attemped by H. H. Yu and Z. Suo in 1999. Yu et al. (1999) studied both the steady and transient motion. A pore can change shape and position affected by evaporation-condensation, surface diffusion, and volume diffusion. In 1964, Shewmon studied the relative importance of these processes and showed that surface diffusion dominates for small pores. In 1983, Hsueh and Evans concluded that the contribution of evaporation-condensation to the transport in Al2O3 is negligible for all reasonable pore sizes (< 10 um). In this study, we assume that surface diffusion is the independent process for the pore to adjust its shape and position and neglect the grain boundary diffusion, so that the volume of the pore remains invariant as it changes shape and position. |

|||||