Conclusions

Creating the code for these simulations and analyzing the results gave us an in-depth look at the mechanisms of micro and nano-scale evolution in thin films with multiple grains.

With the single-layer single-grain simulation, we were able to match the expected theoretical model results that were taught and discussed in lecture. We were able to produce varying results and speeds of evolution simply by changing the constants and forces on the system. While all of the results are not shown as videos, varying the surface tensions of the surface and grain boundaries greatly varied the grain boundary equilibrium angles, the groove angle, and speed of evolution. Also by decreasing the mobility, we were able to change the speed of the evolution, much like changing the timestep used in updating the position of the surface nodes. The differences in the surface migration and surface diffusion regimes were clearly shown by comparing the results when each was set as the dominant evolution mechanism.

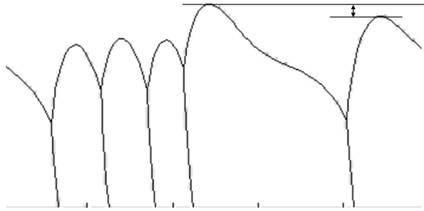

We were able to show the interaction of several grains within the same thin film. This problem has useful applications, as manufacturing of a single-grain thin film is a costly procedure as compared to a film with multiple grains. We were able to show how the diffusion of atoms causes a large ridge to form in the lead of a multiple grain boundary front. In our simulations, the ridge in front of several migrating grain boundaries becomes significantly higher than the ridge in front of a single boundary. Multiple grains moving together seem to have a summing effect on the diffusion of atoms around the group of boundaries. This can be seen in our videos of a single isolated grain boundary with multiple boundaries moving together, as the ridge in the lead of the grain boundaries becomes higher than the ridge in front of a single boundary moving alone, as seen in the figure below.

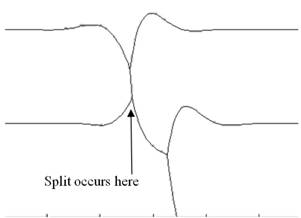

Lastly, we were able to show the interaction of two thin films, one stacked on top of the other. In the first case, we had no driving force on the grain boundary in the top film. Doing so showed the effect of the diffusion of atoms. The upper boundary was forced away from the bottom groove as atoms diffused out of the lower grain boundary. This is an interesting effect, showing that it would not be reasonable for an upper grain to pass a lower grain, and vice versa. The flow of atoms along the surface between the two surfaces would prevent grain boundaries from crossing one another. In the second simulation, by adding a driving force at the bottom of the upper grain boundary at the bottom surface, the grain boundary stayed in the same position. It simply created a groove at the top and bottom that grew until they connected to one another. The boundary split into two separate grains, as seen occurring in the figure below. Therefore, if the upper and lower grain boundaries reached an equilibrium position where they could no longer move due to the diffusion of atoms, the grain boundaries would grow grooves across the film layers until they split. This is an important effect to note, as it would likely cause failure in the film’s particular application.