Simulation Results

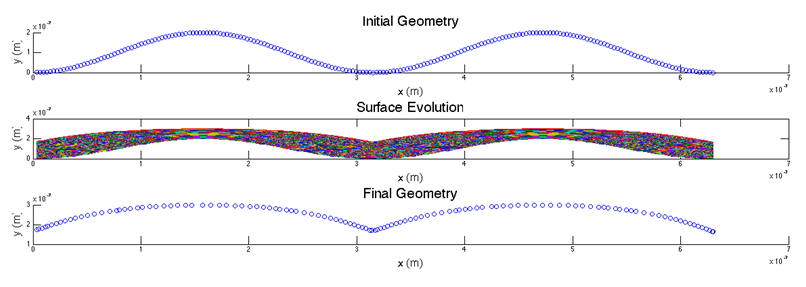

Preliminary tests modeled the evolution of the thin film surface for interface migration by phase transformation only (Fig. 5). Note that the wavy surface becomes flatter over time, which was expected because it would lower the surface energy of the system. Interface mobility parameter L was adjusted to a value of 5x10-17 m2s/kg, such that film growth rate matched experimentally observed deposition rates.

Figure 5 Simulated surface evolution for phase transformation only

(Δt = 4 s)

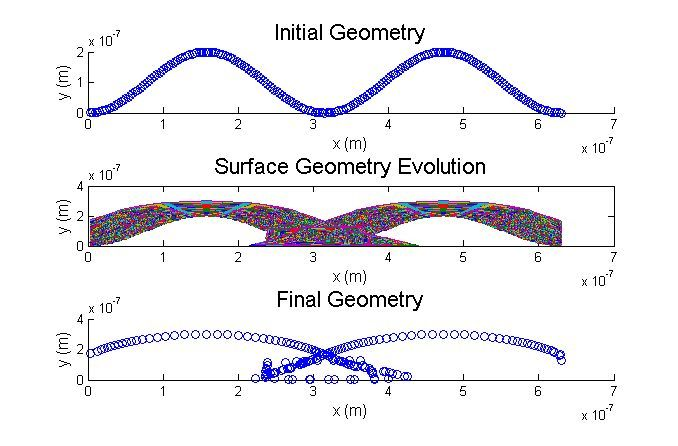

Next, we expanded the model framework to include surface diffusion as an additional mechanism for interface migration (Fig. 6). The mobility parameter M corresponding to surface diffusion was adjusted to an initial value of 10-35 atom2/(N*m*s) to satisfy Lλ2/M ~ 10. The addition of surface diffusion had little effect on the evolution of the thin film surface. Even after varying M by a couple orders of magnitude, the end result was qualitatively similar, although at very high mobilities, the simulation became unstable after relatively few iterations.

Figure 6 Surface evolution with phase transformation and surface diffusion

(Δt = 4 s)

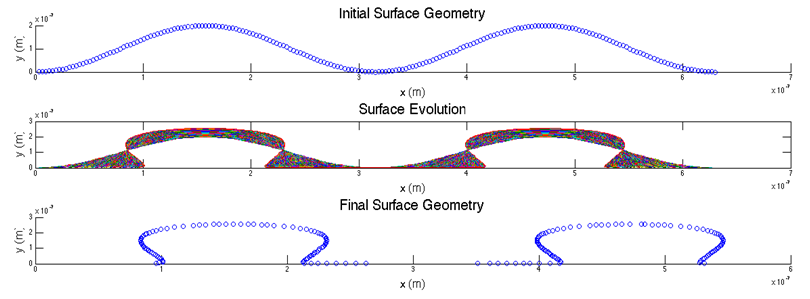

Finally, we incorporated the influence of a thermally-induced elastic stress field σ. In the absence of experimental data/measurements, we selected starting values of σ = 50 MPa and E = 5 MPa, which are in within the range reported in literature studies on other kinds of organic thin films (mostly polymers). As shown in Figure 7 and the following animation, the addition of elastic stress caused the surface to evolve into lobe structures similar to those observed experimentally.

Figure 7 Surface evolution with phase transformation and surface diffusion under elastic stress

(Δt = 4 s)

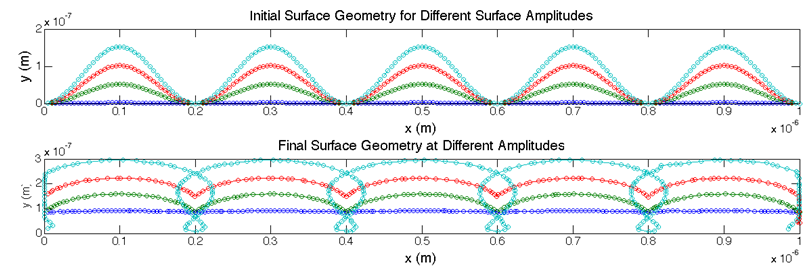

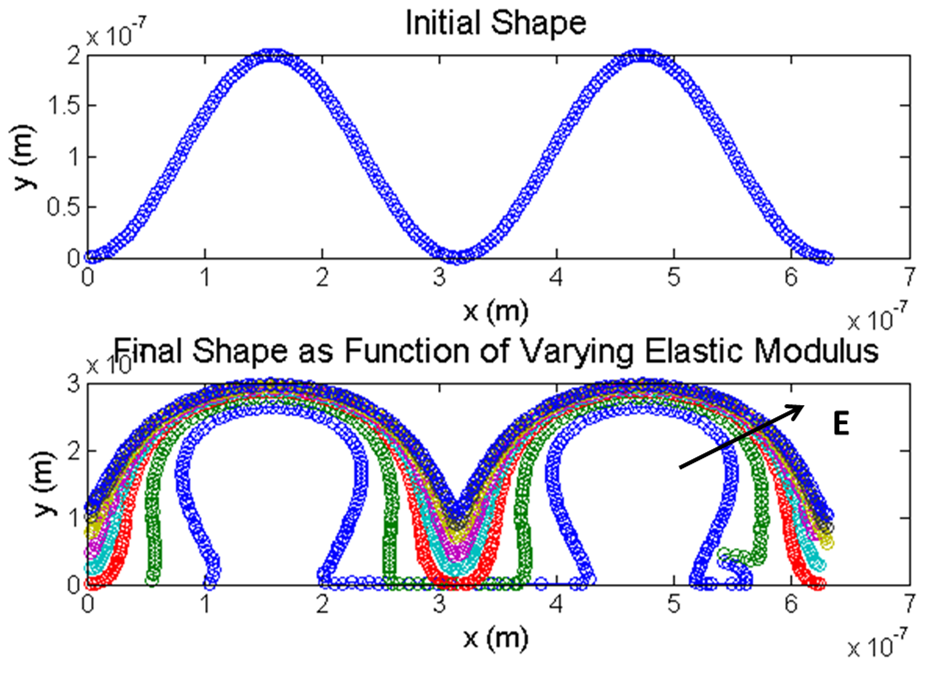

At this point, we investigated the impact of various parameters on the simulated surface evolution. Figure 8 illustrates the influence of the varying the amplitude of the initial surface geometry. It was found that for lower amplitudes (relatively flat initial surface), the surface did not evolve into lobes; instead, the film grew in a similar fashion to the cases without any elastic stress. Figure 9 illustrates the influence of varying the elastic modulus of the film. As expected, for low moduli (soft material), the surface deformed more readily to evolve into lobe structures, whereas high moduli (stiff material), elastic stress played a lesser role.

Figure 8 Surface evolution for different initial surface geometries

Figure 9 Surface evolution for films of different elastic moduli