Introduction

Optically and electrically active organic materials have gained interest over last 20 years due to their ease of processing, compatibility with a wide range of substrates and design versatility. Organic materials can be categorized into two classes: high molecular weight polymeric materials and relatively low molecular weight (< 700 g/mol) small molecules. Small molecule organic thin films are usually deposited using vacuum thermal evaporation (VTE), a technique which requires high vacuum (10-7 Torr) and has very low material utilization efficiencies and slow deposition rates (on the order of 10 Å/sec).

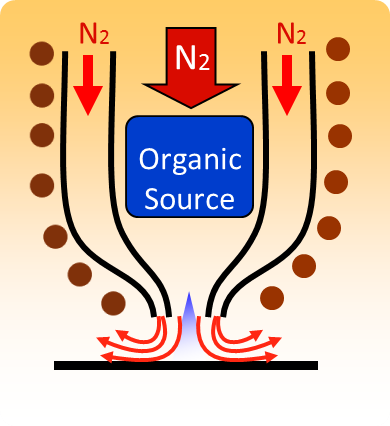

Figure 1 Schematic of OVJP setup

In order to overcome the disadvantages of VTE, the novel technique of Organic Vapor Jet Printing (OVJP) was developed. Using OVJP, the organic material is heated to sublimation temperature and mixed with a hot inert carrier gas, which delivers the material onto the substrate (Fig.1). This enables the material to be locally deposited in vacuum–free environment at high deposition rates (order of 10 nm/sec) and good resolution without the need for masking.

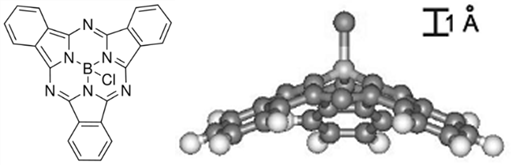

Figure 2Structure of SubPC molecule

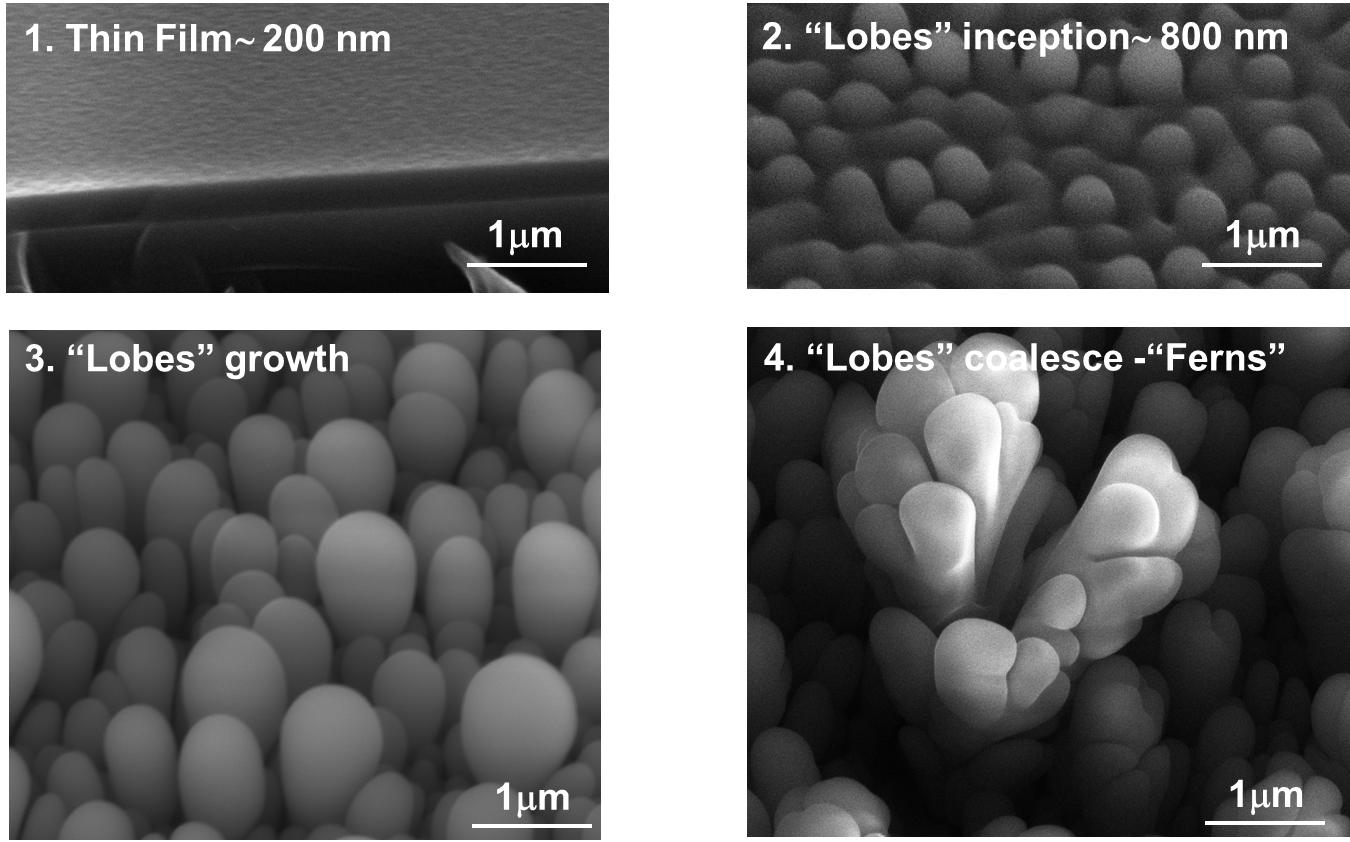

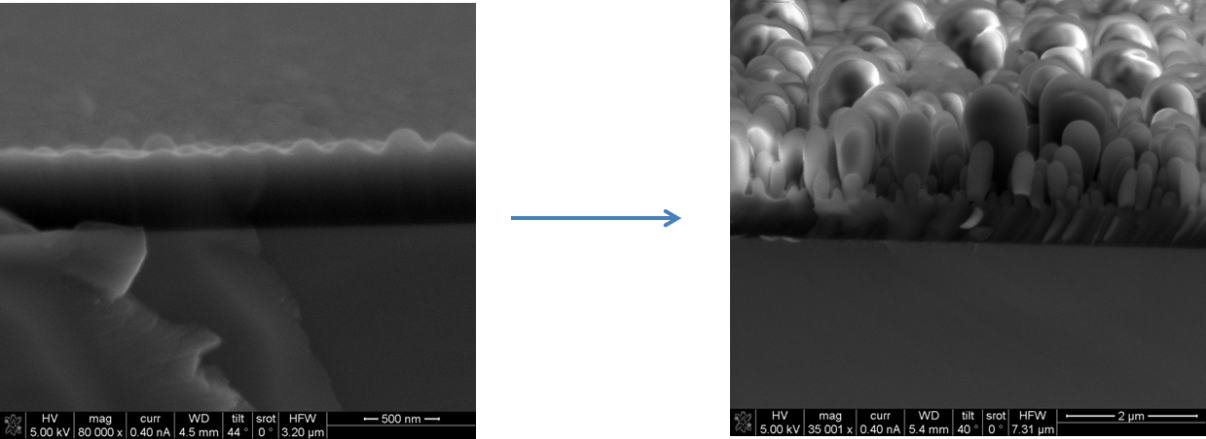

Unique structures on the micro- and nano-scale have been observed in films grown by OVJP. Figures 3 and 4 illustrate the surface evolution of subphthalocyanine chloride (SubPc), a widely-used donor material in small molecule organic solar cells. At a certain critical thickness, the film evolves from a relatively flat surface to a bumpy/wavy surface, and eventually to lobe-like structures. In this project, we sought to model this type of growth using finite element computation.

Figure 3 Evolution of SubPC film; different stages viewed under SEM

Figure 4 Cross sectional SEM images of SubPC films before and after lobe formation