Research: Multi-dimensional Measurements of Velocity during Thermoplastic Injection Molding

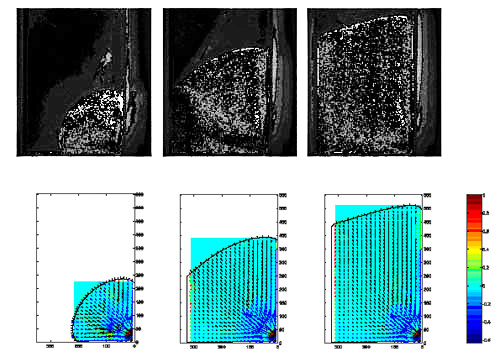

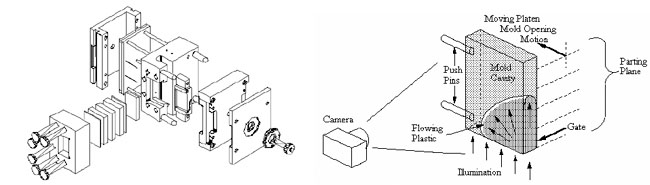

Almost 10% by weight of all new cars is plastic. The most common plastic forming technique is injection molding. Processing parameters have a strong influence on final part properties and molding time, but a clear understanding of these links is lacking. In this project a modern injection molding machine and an optical access mold (shown in the first schematic drawing) are used to quantify the flow of liquid plastic during injection molding of a a rectangular plaque using particle imaging velocimetry. The part orientation is shown in the second schematic drawing. Measured center-plane velocity fields, along with the original images, are shown in the three part series of pictures from an actual mold fill. The plastic is polystyrene.

References:

Bress & Dowling, J. Reinforced Plastics & Composites 17, 1374-1381 [1998].

Bress & Dowling, Polymer Eng. & Sci. 51, 730-745 [2011].

Bress & Dowling, Polymer Eng. & Sci. 53, 770-779 [2013].

Play "Multi-dimensional Measurements of Velocity during Thermoplastic Injection Molding" movie

Current Research Projects

1. Predictions of Acoustic Uncertainty

2. Blind Deconvolution in Reverberant Environments

3. Nonlinear Techniques for Remote Sensing

4. Acoustic Diagnostics for Reverberant Environments

Recent Research Projects

5. Acoustic Coherent Backscatter Enhancement

6. Simulations of Washing Machine Processes

7. Turbulent Boundary Layers At High Reynolds Number

8. Multi-dimensional Measurements of Velocity during Thermoplastic Injection Molding

9. Beyond Line-of-sight Acoustic Sensing

10. Measurements of Oil-film Thickness