Objective: Working-time of an elastomeric-impression-material is a vital property. If an elastomeric-impression-material is inserted into the mouth after it has begun to set (develop-elastic-properties), a certain amount of elastic-recovery will occur when the impression is removed; therefore, the impression will be distorted resulting in a cast that will be too small by the amount the impression-material recovered. The objective of this work is to report a method to measure the working-times of elastomeric-impression-materials while simultaneously measuring rheological-properties and to use this method to determine working-times and associated viscosities of nine-different light-bodied-consistency elastomeric-impression-materials.

Methods: A Brookfield-Model-R/SR-CPSTP1-Plus-Cone/Plate-Rheometer with Peltier-temperature-control-system was used in Control-Shear-Stress-mode. Brookfield-Rheo-2000-Software-program was used to apply a constant-shear-stress(Tau) of 450Pa (determined from pilot-testing) to the elastomeric-impression-material for 10seconds and then unload for 10seconds. This cyclic-loading and unloading was repeated for a pre-determined time-period (typically, 3minutes). Tests were performed using a-plate-and-plate test-configuration (25mmDiameter-plate with 0.3mm-gap between bottom-stationary-plate and upper-rotating-plate). Temperature of rheometer-plate was 23�0.1�C or 35�0.1�C. Pilot-testing was performed on each elastomeric-impression-material to determine how many seconds after start of mixing to start rheometer-program. A starting shear-rate less than 10reciprocal-seconds was the goal for when to start the program (this minimized effects of high shear-rates during setting on properties). The software-program recorded several variables with respect-to-time (one-data-point-per-second). Critical variables include: shear-rate(D),shear-stress(Tau),viscosity,rpm-of-spindle, distance-spindle-rotates(Phi,radians), strain(Gamma), modulus(Tau/Gamma), torque, creep(J). During a test, when the material begins to develop elasticity, the top-plate will rebound (�bounce-back�) to a measurable degree during un-loading (constant-shear-stress released). The time at the end of the previous-cycle (before-rebound-indicated) plus the amount of time from start-of-mixing to start of rheometer-program (monitored with stop-watch) is the working-time (Fig.1 illustrates data-analysis).

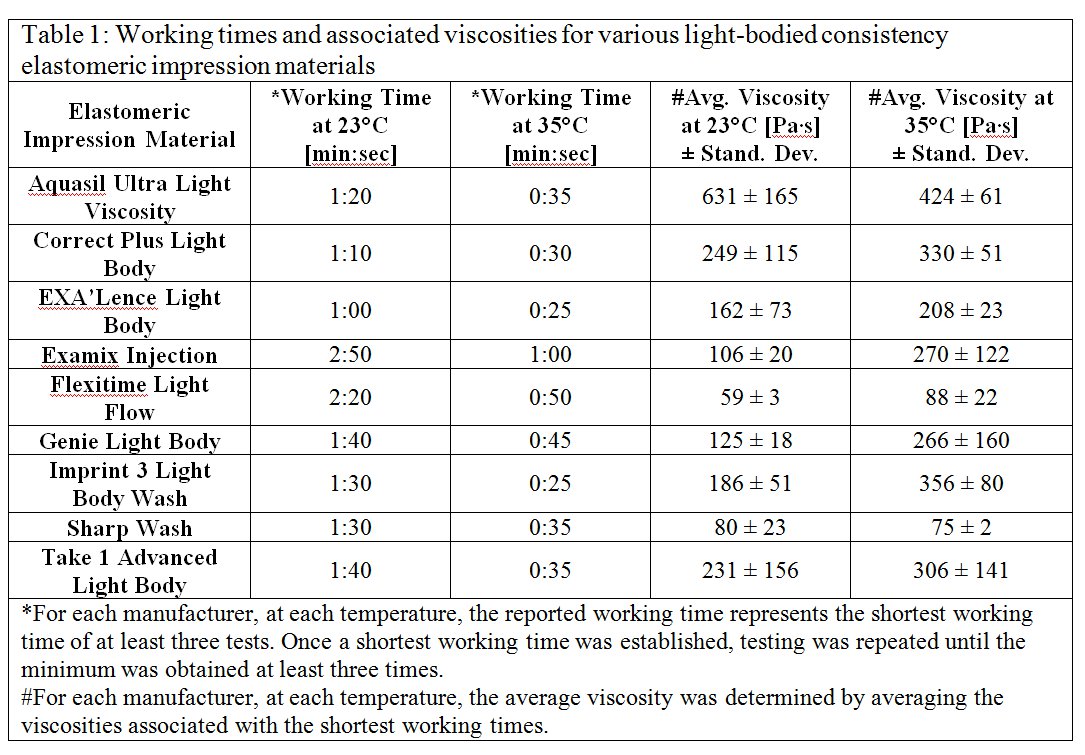

Results: See-Table1.

Conclusions: A method for simultaneous determination of working-times and rheological-properties of elastomeric-impression-materials is reported along with the results of using this method to determine working-times and associated-viscosities for different light-bodied-consistency elastomeric-impression-materials.

Keywords: Dental materials, Elasticity, Impression materials and Rheological

![[ Visit AADR's Website ]](images/banner.jpg)