Objectives:

The objective of this study was to describe a computer-controlled, rope-brake dynamometer for testing torque, power, and associated performance characteristics of dental air-turbine handpieces and report on the use of this testing machine on both a conventional and disposable air-turbine handpiece.

Methods:

The test-system includes a computer-interface for the input of test parameters and subsequent output of test data. The system has the ability to provide information on the following essential performance characteristics: rotational-speed (i.e., free-running, vs-supply pressure, vs-torque), dynamic torque (torque-vs-speed), stall torque, bearing-resistance, power-generation (i.e., power-vs-speed, power-vs-torque), and efficiency. In general, a highly-polished tungsten-carbide mandrel of known radius is inserted into the handpiece being tested, which is mounted in the test-system. Silk suture-thread is then wrapped around the mandrel, and the thread is aligned with custom bearing-guides and attached on each end to force-sensors (Interface), using custom thread-mounts. The force on the thread is controlled through one of the force-sensors mounted on a computer-driven linear-stage (ThorLabs). An optical-infrared tachometer (Monarch) measures the rotational speed of the mandrel.

Data from the sensors for force, speed, and air pressure is acquired with a National-Instruments CompactDAQ system and monitored and recorded with a custom-designed LabVIEW program. The data is then analyzed with a custom-script written in DIAdem (National-Instruments). Using a previously-reported procedure by Dyson&Darvell, a correction factor for the thread-radius, which allowed improved accuracy in torque and power calculations, was determined by measuring torque at stall with 3 different mandrels of known radius.

Results:

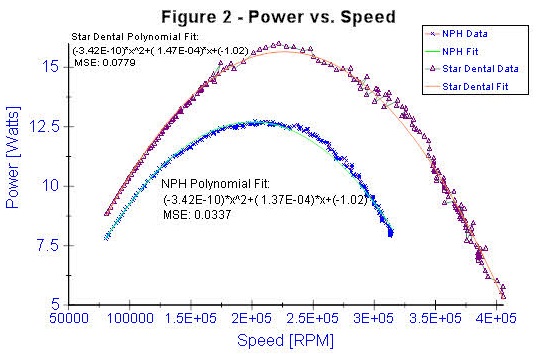

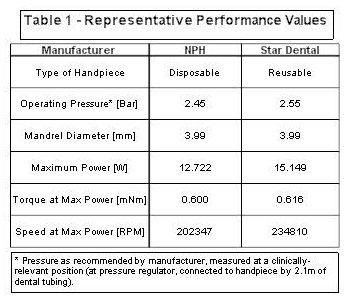

See Figure-1 and Figure-2 for sample speed-vs-torque and power-vs-speed curves, respectively, and Table-1 for important values from the sample curves.

Conclusion: A testing machine for evaluating torque, power, and

associated performance characteristics of dental air-turbine handpieces is reported along with use of this testing

machine on both a conventional and disposable air-turbine handpiece.

Keywords: Dental materials and Technology

See more of: Dental Materials 10: Instruments and Equipment

![[ Visit AADR's Website ]](images/banner.jpg)