Objective: With their relatively high water content and associated hydrophilicity, alginate impression materials are susceptible to tearing when removed(“snapped”) from the mouth. Marginal tearing of an impression material can reduce the accuracy of the final cast. Boghosian and Lautenschlager(IADRAbstract2003) have reported on the tear strengths of low-viscosity elastomeric impression materials using notched specimens meant to represent the average marginal thickness of clinical impressions. The objective of this study was to use an axial-notched mold to compare the tear strengths of various alginate impression materials.

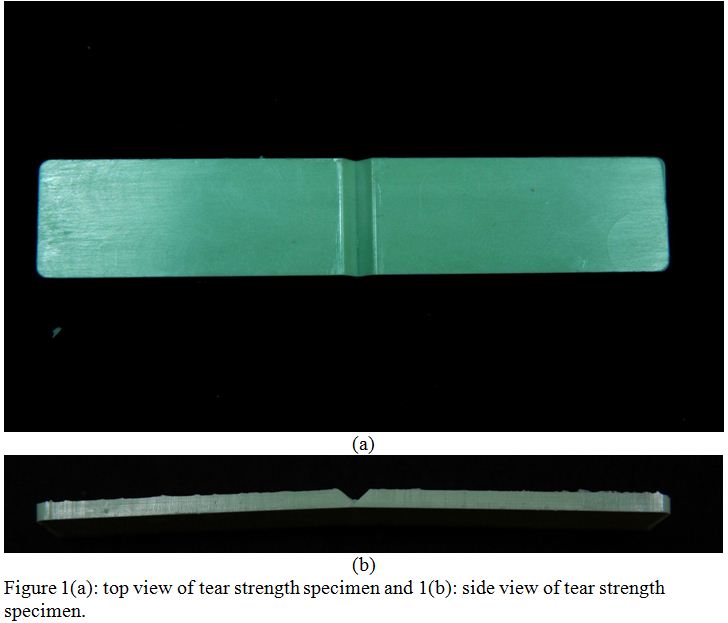

Methods: A v-notched tear strength mold with the following dimensions was used in this study 101.6mm longX19.05mm wide with v- notched region approximately 0.230mm-thick(SeeFig.1a-1b). Hand-spatulated specimens were placed in the mold (conditioned to 35°C) exactly one minute after start of mix. The specimens were then stored in a water bath at (35±1°C) for the manufacturer's-recommended time to leave in the mouth(minimum time to remove from mouth). Within 90sec of removal from the water bath (specimens were transported in a damp paper towel), the top and bottom 1-inch of the specimen was gripped in the Instron5582 equipped with pneumatic grips (17-20psi) and 240-grit abrasive paper. A tensile force was applied at a cross-head speed of 500mm/min until failure. A razor was used to slice three sections 1-mm wide from the notched region of the torn specimen. The thickness of each section was measured using a Nikon profile projector. The average thickness (ha) of the notch cross-section was used to calculate tear strength, Ts(MPa) using the following equation:

Ts=F/(ha x w),Ts=tear strength(N/mm),F=maximum force(Newtons),ha=average thickness(mm) w=specimen width(mm).

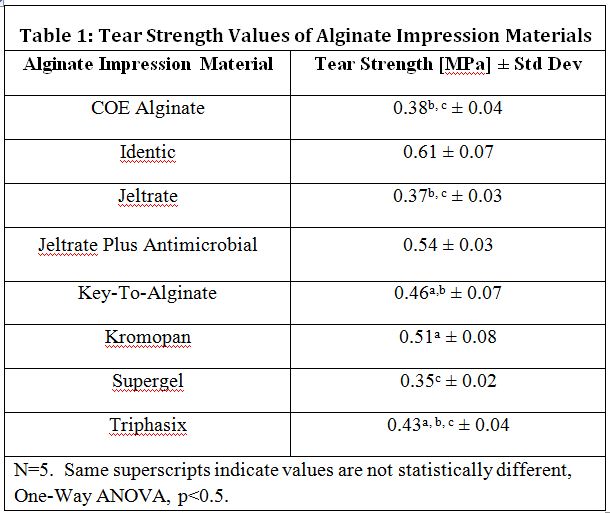

Data was analyzed using One-WayANOVA(p<0.05).

Results: See Table 1.

Conclusion: A test method using an axial-notched mold was successfully employed to determine tear strength values of various alginate impression materials and report statistically significant differences.

Keywords: Impression materials

![[ Visit AADR's Website ]](images/banner.jpg)