Oxygen:

Cylinders, Concentrations, Grades, and Labels

by

Larry

"Harris" Taylor, Ph.D.

This material is copyrighted and all rights retained

by the author. This article is made available as a service to the diving

community by the author and may be distributed for any non-commercial or

Not-For-Profit use.

All

rights reserved.

Go

To: Home

About

"Harris" Articles

Slides

War Stories

Editorials

Links

Fini

Jump

to: USP Grades

Cylinders Label Legal Litigation

Prescriptions Praxair

SB-107 Recommendation

The use of oxygen, particularly in recreational gas mixes, is often a topic for

debate, posturing, and rhetoric. This article summarizes the various terms and usage associated with

compressed gas cylinders containing oxygen for human respiration and medical

procedures.

Oxygen

Oxygen is a chemical element that exists

in the atmosphere as a stable molecule containing two atoms (O2).

The element has an atomic weight of 16; the molecular weight is 32.

Oxygen is one of the most abundant

chemical elements on earth. Like most gases, oxygen is colorless, odorless, and

tasteless. It is chemically reactive and readily combines with a variety of

materials. Although by itself oxygen is not combustible, the ease with which it

reacts with other materials can lead to fires and explosions if improperly handled. Mixtures above 21-23.45 % O2 are considered

oxygen-enriched atmospheres by the Compressed Gas Association (CGA) and the

National Fire Protection Association (NFPA). The risk of fire/explosion

increases with increasing oxygen partial pressure and/or concentration. Handling

oxygen-enriched atmospheres requires specialized equipment and training.

Oxygen

is essential for life. The body uses chemical reactions based on oxygen to

generate heat and chemical energy. This process, called metabolism, keeps us

alive. The oxygen in the breathing gas must be maintained within certain limits.

Too little oxygen (hypoxia) can be fatal. Too much oxygen (hyperoxia) can lead

to CNS (Central Nervous System) oxygen toxicity with the possibility of seizures

at depth or a more long term development, whole body or pulmonary oxygen

toxicity. These

toxicity concerns for the oxygen provider are discussed here.

Almost

all the oxygen (as well as nitrogen and argon) manufactured in the US is

prepared from the fractional distillation of liquid air. In this process, air is

chilled to a liquid state and then gradually warmed so that oxygen, nitrogen and

argon (which have different boiling points) can be separately collected

and packaged. Additionally, a small

amount of oxygen is prepared from the electrolysis of water or from solid-state

chemical reactions.

USP

Entry for Oxygen

The United States Pharmacopoeia

(USP) is a listing (compendium) of drugs licensed for use in the United States

with the analytical standards necessary to establish purity suitable for human

use applied to each of the listed drugs. Drugs sold

for human consumption in the US must meet or exceed the purity standards listed in the USP.

Drugs meeting these requirements must include a designation on their label that

demonstrates compliance with standards listed within the USP; typically, this is

shown as the initials USP immediately following the name of the drug. Many nations

have their own Pharmacopoeia to list and specify requirements for drugs legally sold within their borders.

To be labeled

Oxygen, USP, the gas cylinder must contain a documented minimum of 99.0 percent oxygen by

volume and be odor free. The label must also specify whether the oxygen gas was

produced by the fractional distillation of air (also called air-liquefaction

process) or other means. If produced from liquid air, then the cylinder contents

may be labeled USP without an analysis for either carbon dioxide (CO2) or carbon

monoxide (CO).

It is illegal

in the US to sell non-USP drugs (including oxygen) for human consumption.

Oxygen Grades

The US Department of Transportation (DOT)

classifies oxygen as a non-flammable

compressed gas. The Compressed Gas

Association (CGA) has designated various grades of oxygen based on analysis of

the contents of an oxygen cylinder. The table below, unless otherwise

specified, lists possible contaminant components in parts per million (ppm) and

the

analytical standards for each of the various defined grades. A blank entry means

that there is no specification or test required for the listed component in the

appropriate grade column.

Grade A is the

minimum requirement for USP oxygen. Grade E is commonly called aviator's grade.

Grade

of Oxygen Gas

|

Content

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

|

Oxygen

Min. % (mole)

|

99.0

|

99.5

|

99.5

|

99.5

|

99.6

|

99.995

|

99.5

|

|

Water

(v/v)

|

|

|

50

|

6.6

|

8

|

1.0

|

2

|

|

Dew

Point (oF)

|

|

|

-54.5

|

-82

|

-80

|

-105

|

-97

|

|

Methane

|

|

|

|

50

|

|

|

|

|

Nitrogen

|

|

|

|

|

|

|

100

|

|

Ethylene

|

|

|

|

0.4

|

|

|

|

|

Acetylene

|

|

|

|

0.1

|

|

|

|

|

Carbon

Dioxide

|

300

|

|

|

10

|

|

1.0

|

5

|

|

Carbon

Monoxide

|

10

|

|

|

|

|

1.0

|

|

|

Total

Hydrocarbons (as methane)

|

|

|

|

|

50

|

1.0

|

25

|

|

Ethane

& Other Hydrocarbons

|

|

|

|

6

|

|

|

|

|

Nitrous

Oxide

|

|

|

|

4

|

|

0.1

|

2

|

|

Halocarbons

|

|

|

|

2

|

|

|

|

|

Solvents

|

|

|

|

0.2

|

|

|

In addition,

there are a variety of terms used in the lay community that have been used

to describe various grades of oxygen. These sometimes are specific to a local

community or state. One of he most

intense discussions commonly encountered in discussing oxygen use for diving centers

on the term "welding gas." This is primarily only of historical

interest.

Many moons ago,

gas supply vendors typically maintained two separate storage facilities for

oxygen: " welding or industrial or technical" (a non-USP, or illegal to sell

for human consumption label) variety and gas intended for

human use in respirators or medical procedures (a USP label). Since most gas supply vendors have decided that it is simply not

cost-effective to store separate grades of medical gases, almost all oxygen

sold in the US is a USP grade (meets USP requirements for human consumption).

However, there are distinct differences in how the cylinders are filled. (see

below). So, the debate as to whether to use a non-USP welding gas or a USP

medical grade oxygen for diving is mostly irrelevant since most vendors are now

filling all cylinders with USP gas.

Typically, when

filling an incoming oxygen cylinder, the fill station operator opens the

cylinder valve and "sniffs" the valve opening. If acetylene is smelled

(an indication of improper shut down procedures in a welding operation), the

cylinder is set aside to be cleaned at some later time (to remove the odor

from acetylene and thus prevent a potential explosion from an acetylene-oxygen

mix within the cylinder). If no acetylene is smelled, then a whip is

connected to the cylinder and the "welding" cylinder is filled with USP oxygen.

If the vendor

fill station operator sees that a cylinder is labeled as a medical or emergency

oxygen cylinder, or intended for human respiration, then the cylinder is evacuated (see below) and filled with USP oxygen.

So, the difference between a

modern US "welding" oxygen or "medical" or "respiratory"

oxygen

cylinder is not the quality of the oxygen gas used to fill the cylinder,

but the manner in which the cylinder is filled (and the legal consequences of

inappropriate fill procedures) and the FDA labeling requirements.

Today in the

US:

Most

welding or

Industrial grade oxygen cylinders are filled with USP oxygen without an evacuation-between-fills

step.

Respiratory

grade oxygen cylinders are filled with USP oxygen with an evacuation-between-fills

step.

Medical grade

oxygen cylinders are filled with USP oxygen with an evacuation-between-fills step

(Some states

differentiate between a respiratory and medical grade. Typically, the cylinder

contents are the exactly the same, but the label is different. Historically, this was

done to avoid prescription requirements for emergency/rescue organizations using pure

oxygen respirators.)

Aviation grade

oxygen cylinders are filled with USP oxygen that has undergone additional drying

steps with an evacuation-between-fills step. The low quantity of water is a precaution against

oxygen line freezing that might occur with higher water content at the chilled

temperatures found at altitude. (Typically, "regulator freeze-up" is a

result of chilled water vapor within the gas mix condensing and then freezing

... a chunk of ice may block gas flow or interfere with mechanical operation of

valve/regulator mechanisms. So, lowering water vapor content of a gas mixture lessens the likelihood of a

"freeze-up.")

Grade 4.5

oxygen is USP oxygen that has a purity greater than 99.995 % oxygen

Grade 5 (or

"five nines") oxygen is USP oxygen that is certified 99.999 % pure. It is sometimes called

research grade. This is the highest purity of oxygen manufactured in

the US and is typically found only in top-end chemical research facilities. Its

non-research use is associated with specialty welding of titanium and titanium

alloys for the nuclear or aerospace industry.

For divers, the

best oxygen available for deco or oxygen-enriched air breathing mixes is

aviation grade oxygen.

For emergency-only (DAN) cylinders, the only legally

acceptable gas is medical grade oxygen supplied by an FDA licensed facility. (see legal

stuff, below).

The

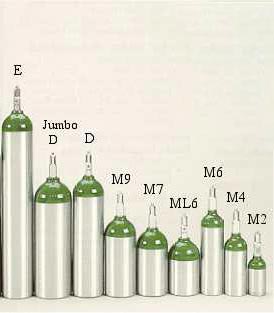

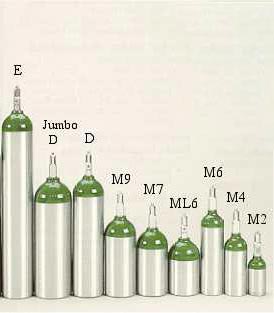

Cylinders

The

use of oxygen, particularly in recreational gas mixes, is often a topic for

debate, posturing, and rhetoric. This table summarizes the various types of

compressed gas cylinders containing oxygen for human respiration and medical

procedures.

|

Cylinder

Size

|

Oxygen Capacity

|

Service Pressure

|

Cylinder Length

|

Cylinder O.D.

|

Cylinder Weight

|

|

| |

CU. - LITER

|

PSI - BAR

|

IN. - CM

|

IN. - MM

|

LBS. - KG

|

|

MM

|

122 - 3455

|

2216 - 153

|

35.75 - 90.8

|

8.0 - 203

|

38.6 - 17.55

|

|

M60

|

61.4 - 1738

|

2216 - 153

|

23.0 - 58.4

|

7.25 - 184

|

21.7 - 9.86

|

|

E

|

24 - 680

|

2015 - 139

|

25.63 - 65.1

|

4.38 - 111

|

7.9 - 3.58

|

|

Jumbo D

|

22.6 - 640

|

2015 - 139

|

16.3 - 41.4

|

5.25 - 133

|

8.1 - 3.68

|

|

D

|

15 - 425

|

2015 - 139

|

16.51 - 41.9

|

4.38 - 111

|

5.3 - 2.41

|

|

M9

|

9 - 255

|

2015 - 139

|

11.88 - 27.6

|

4.38 - 111

|

3.7 - 1.69

|

|

M7

|

7 - 198

|

2015 - 139

|

9.18 -23.3

|

4.38 - 111

|

3.3 - 1.48

|

|

ML6

|

6 - 165

|

2015 - 139

|

7.68 - 19.5

|

4.38 - 111

|

2.9 - 1.29

|

|

M6

|

6 - 165

|

2216 - 153

|

11.59 - 29.4

|

3.2 - 81

|

2.2 - 1.0

|

|

M4

|

4 - 113

|

2216 - 153

|

8.4 - 21.3

|

3.2 - 81

|

1.6 - .74

|

|

M2

|

1.4 - 40

|

2216 - 153

|

5.37 - 13.6

|

2.5 - 63.5

|

.74 - .34

|

The Label

The label from

one of my E (~650 liter) cylinders is shown below (large enough to read the

print).

The label designates

the following:

Oxygen,

Compressed USP

This cylinder contains compressed oxygen gas that meets the purity standards for

human use as defined by the United States Pharmacopoeia

(USP).

UN 1072

The DOT chemical compound identification number is 1072. This is a reference to the

Material Safety Data Sheet (MSDS) which lists physical properties, special handling

precautions, chemical reactivity, health hazards, waste disposal and

transportation requirements for the cylinder contents. (US OSHA regulations

mandate that all chemicals sold in the US be accompanied by a MSDS to

facilitate safety when handling purchased chemical materials.)

Yellow

Diamond

This is a

reference symbol established by the National Fire Protection Agency (NFPA)

to quickly identify the nature of potential hazards associated with the chemical

contents of a container. The yellow color implies the contents may contribute to

substantial releases of energy. This symbol contains the name of the

chemical, Oxygen, and identifies it as a combustion hazard (the fire symbol) with

a relative danger of 2 (of 4 possible). The relative danger of 2 suggests

a potential of

violent combustion, an increased fire threat typically without immediate detonation.

Contents

This blank

allows the vendor to specify volume of contents contained within the cylinder at

the time of filling.

Warning

This is this

the legal consumer product safety warning. Notice that this label allows filling

of emergency-only cylinders without prescription,

Produced by

Air Liquefaction

Identifies the method

of manufacturer that exempts contents from required-for-USP-label carbon dioxide or carbon

monoxide analysis.

Warning

Specific

hazards associated with the chemical nature of oxygen. The Chemical Abstracts

Service (CAS, a chemical organization that abstracts all published chemical

journals, as well as assigning unique numbers to all chemicals known as they are

discovered) identification number for oxygen (CAS 778244-7) is also provided as

a reference to the chemical and physical properties of the cylinder contents.

The caution to use in accordance to the MSDS refers to a reference document (the

Oxygen MSDS furnished by the manufacturer) that lists known concerns about the safety issues associated with

handling the contents of the cylinder.

Do

Not Remove

FDA requires that drugs always be properly labeled such that the

contents are readily identifiable.

The Vendor

The label must contain the source of the drug (in this case, Ann Arbor Welding

Supply) since this FDA licensed facility will have records required by FDA Good

Manufacturing Practices on the handling of the gas contained in the cylinder.

The Legal

Stuff

Before

mentioning the FDA regulations for compressed medical gases, it should be

pointed out that any business in the United States that has employees must meet both Federal and State

compliance with respect to Occupational Health and Safety Regulations ( OSHA).

Although originally intended for chemical laboratories, an additional program

called "chemical hygiene" is observed by many business operations.

"Chemical Hygiene" can be interpreted as having safety data (typically as MSDS (Manufacturing

Safety Data Sheets)) for all chemicals (including compressed gases) on the

premises. In addition, the employer must document that all employees have been briefed

on specific hazards and procedures associated with every chemical present at the

business location. To

document OSHA compliance, various agencies will supply checklists to assist

employers in meeting these guidelines. Failure

to meet OSHA guidelines can be quite expensive since OSHA has the power to issue

daily fines and close a business until compliance is documented. Wise business

owners will seek legal advice to understand steps necessary for compliance with

local and Federal OSHA regulations.

The US Federal Drug Administration (FDA)

classifies oxygen as a compressed medical gas (CMG)

and, as such, it must

be handled in accordance with the appropriate federal guidelines. Use of oxygen

as a CMG is covered by a minimum of 2 separate

federal documents: Title

21 CFR Parts 200-211 (drug labeling act) and the FDA Medical Gases Guidelines

( as a PDF

file from the FDA )

Basically,

most "civilized" nations require that drugs

intended for human use be prepared under guidelines that have been called "Good Manufacturing Practice (GMP)." The GMP is a set of protocols

supervised in the US by the FDA that

require all steps, from initial manufacture to dispensing of the

drug to the consumer, document the purity of the material being distributed.

So, each phase of drug distribution must maintain records of drug analysis and

handling consistent with the standards defined for the specific drug in the USP and GMP guidelines (analogous to a legal "chain of

evidence"). Compressed medical gas cylinders can be legally filled only at

a FDA inspected and licensed facility.

For medical

gases, including oxygen, the primary GMP protocol that affects divers is the

transfilling (moving gas between storage and use cylinders) requirement. The FDA Guidelines

for this step state:

Requirements

for drug containers:

Section 211.94(c) requires that drug product containers be clean.

Section 211.94(d) requires that standards or specifications, methods of

testing, and, where indicated, methods of cleaning be written and followed for

drug product containers.

Guidance

One factor to consider regarding the above requirements is the possible

presence of foreign gas residues in CMG cylinders before filling. An acceptable

method of assuring that cylinders do not contain foreign gas residues is to pull

a vacuum on each cylinder equal to 25 or more inches of mercury prior to filling

with the CMG. (Cryogenic vessels are seldom completely emptied and need not be

evacuated before filling.)

Most medical

cylinders and emergency response respirators using oxygen are used repeatedly; often the same cylinder may be used in a variety

of locations with differing practices of handling cylinders. The requirement of always

evacuating a cylinder, regardless of cylinder pressure, is a step intended

to minimize contamination that might occur from "back-filling" of a cylinder

improperly connected to a gas cascade system, or left open to the atmosphere for

extended periods of time. It also prevents the accumulation of possible

contaminants from repeated fills from a compromised source. The primary distinction of oxygen cylinders intended

for medical (emergency applications are also medical procedures) procedures and

respirators and

all other uses is

this evacuation step between fills.

The

Compressed Gas Association publication P-2.5, Transfilling of High Pressure

Gaseous Oxygen To Be Used For Respiration, states that the transfilling station

should consist of "a supply cylinder unit, a receiving cylinder

unit, a cylinder evacuation unit, a gas transfer control unit, and detailed

written procedures."

So, the cost of

filling an oxygen cylinder intended for medical or emergency-only or for human

respirators service is

primarily not

a function of the gas cost, (300 - 700 liter consumer cylinders are

typically filled for the same price), but the price for the required documented analysis

associated at each

step of

distribution and the equipment necessary at each step to evacuate a 100% oxygen

cylinder to a significant vacuum prior to refilling. There is also the

assurance that the cylinder contents have been validated at each handling step.

While many

divers might consider this evacuation-between-fills step unnecessary, it is considered by the FDA to be an

essential requirement for medical grade gasses. While rare, there have been

injuries and fatalities associated with failure to evacuate oxygen cylinders

between fills. As such, the evacuation step is considered by the FDA to be absolutely essential

in filling cylinders intended for medical (emergency) use.

The

FDA does prosecute the inappropriate filling of oxygen cylinders by unlicensed

facilities.

From the

Medical Gas Guidelines Appendix:

QUESTION: What are the penalties for violating the Act?

ANSWER: If found guilty of violating a provision of the Act, an officer or

employee of the firm may be imprisoned for up to one year and/or fined up to

$100,000 ($250,000 if death occurs) for each violation. If the prohibited act

was committed with intent to defraud or mislead or if an officer or employee is

convicted a second time under the Act, the offense is punishable by a fine of

$250,000 to $500,000 and imprisonment of up to three years for each violation.

The firm can also be fined the same amounts. (Note: The limits of the amount of

fine that can be imposed were raised by the Comprehensive Crime Control Act of

1984, for all criminal violations for which the basic Federal law imposes a

prison sentence of six months or more.)

One interesting feature of the law as written is

that as long as the oxygen gas is USP, it may be used for mixing all sorts of

concentrations of oxygen containing breathing mixes. However, the transfilling

of 100% oxygen into cylinders intended for medical or emergency-only

cylinders requires that the FDA license the transfilling station and that

all cylinders filled with compressed medical gas be filled according to FDA

specified GMP procedures.

Accident Litigation

It is pretty much a

given in the US that a dive accident will lead to litigation. In such an event,

the plaintiff will explore as many as possible avenues to convince a

jury that the defendant was not a responsible, caring person ... someone whose

disregard of accepted safety standards was the proximate cause of an injury or

death. If oxygen was on the site and used in accident management, then the

nature of the cylinder contents becomes a legal matter. Using a FDA licensed facility

as a medical gas vendor facilitates defense; use

of FDA non-compliant cylinders, irrespective of the actual gas purity,

potentially provides the

plaintiff (and jury) with documentation that the defendant was acting outside the law.

Prescriptions

The historical

basis of prescriptions for oxygen is discussed in the article Rx:Oxygen.

Historically, there have been 4 types of oxygen cylinders exempt from

prescription requirements. These are cylinders used only for:

1.

emergency use by trained personnel

2.

chemical/medical research or education

3.

extremely limited capacity

4.

private or commercial aviation

However, medical insurance providers, either

third party or the federal government, pay for most non-hospital use of oxygen

cylinders. This means the oxygen supply vendor is often

audited to document amounts of gas distributed and the conditions of distribution.

Regardless of the nature of an emergency-only cylinder, it is simply easier and

more convenient to provide the oxygen supplier with a prescription. Besides,

many commercial vendors will simply not fill an oxygen cylinder for individuals without a prescription.

This

is how I handle the situation.

Each

year (Michigan limits oxygen prescriptions to one year), I have a physician write me a prescription for "oxygen to be used in

dive accident management or education." This satisfies the vendor's need

for documents when audited and allows me to fill my cylinders. I keep a photocopy

of my personal prescription for oxygen in my DAN O2 case, in case there is

ever a need to refill a used oxygen cylinder while traveling.

DAN

Agreement With Praxair

The

Diver's Alert Network (DAN) has made arrangements with a commercial

medical gas supplier, Praxair, to assist divers in filling their DAN oxygen

cylinders.

CGA SB-107

In 1992, the

Compressed Gas Association issued a special warning about oxygen cylinders to

the diving community; special bulletin 107 (SB-107). This was a result of

several catastrophic failures during refill operations of oxygen cylinders that

had been immersed in ocean water. These failures included several fatalities of

fill station operators. It has now been documented that water can enter a

cylinder via the regulator when the purge is depressed, regardless of cylinder

gas pressure. The combination of seawater with high oxygen concentration can

destroy the integrity of a steel cylinder within 30 to 60 days. As such, the CGA has recommended:

1. if

possible, do not submerge cylinders containing high concentrations of oxygen

2.

cascade system working pressure should never drop below 2 x the

at-depth pressure.

3. never

transfill oxygen (or any other gas) cylinders without the owner's consent.

So, What

to do?

Personally, I

get my oxygen-enriched mixtures from my local dive shop (that uses aviation

grade oxygen in their gas mixing operations). However, I will only fill

my DAN O2 cylinders (and additional D & E cylinders used in

teaching DAN O2 classes) from an FDA licensed transfilling station. To me, a reasonable and prudent person would always

fill their emergency response cylinders at an FDA licensed facility.

Another

guideline I use is that if the cylinder has a scuba regulator compatible valve,

then I fill the cylinder at a dive shop. However, any oxygen cylinders with a

medical regulator valve (uses the pin-indexing system) are only filled at a FDA

licensed facility.

References

-----,

COMPRESSED MEDICAL GASES GUIDELINE, U.S. Public Health Service, Food & Drug

Administration, Rockville, MD. 1989, 24 pages.

From CGA

G-4:

Oxygen, 1987, 16 pages.

G-4.3:

Commodity Specification for Oxygen, 1988, 12 pages.

P.2.5

Transfilling of High Pressure Gaseous Oxygen To Be Used For Respiration, 13

pages, 1992.

SB-7:

Rupture of Oxygen Cylinders in the Diving Industry, 1980, 2 pages.

From NFPA

-----,

"Medical Gases," Chapter 7 in NFPA Fire Protection Handbook, p. 5-49 -

5-57.

Top

Jump

to: Oxygen USP Grades

Cylinders Label Legal Litigation

Prescriptions Praxair

Go

To: Home

About

"Harris" Articles

Slides

War Stories

Editorials

Links

Fini

About The

Author:

Larry

"Harris" Taylor, Ph.D. is a biochemist and Dive Safety Coordinator at the

University of Michigan. He has authored more than 200 scuba related articles.

His personal dive library (See Alert Diver, Mar/Apr, 1997, p. 54) is considered

one of the best recreational sources of information in North America.

Copyright 2001-2024 by Larry "Harris"

Taylor

All

rights reserved.

Use

of these articles for personal or organizational profit is specifically denied.

These

articles may be used for not-for-profit diving education