Following are the research projects we have worked in the recent past, listed in alphabetical order. This simply means there is currently no student working on them. They can become active topics anytime with interested students and funding availability as we believe there are plenty of opportunitiesd for further investigation.

- Click here to see an article on our group in the 2015 ME Anual Report.

Assembly Synthesis for Component Modularity

The goal of this project is to develop a computational method to identify modular structural components that are sharable among multiple structures. The method simultaneously decomposes the multiple structures with given geometries such that the reduction of structural strength of each structure due to the introduction of joints, and the overall manufacturing cost are minimized. The types of welded joints at component interfaces are selected from a given library, and the manufacturing costs of components are estimated under given production volumes considering the economies of scale. A multi-objective genetic algorithm is utilized to allow effective examination of trade-offs between manufacturing cost and structural strength.

Assembly Synthesis for Robust Dimensional Integrity

The goal of this project is to develop a computational method to design an assembly and the corresponding fixture schemes and assembly sequence, such that the dimensional integrity of the assembly is insensitive to the dimensional variations of individual parts. The method recursively decomposes a given product geometry into two subassemblies until parts become manufacturable. At each recursion, joints are assigned to the interfaces between two subassemblies to ensure the in-process dimensional adjustability and proper part constraints.

ChemReader : Automated Annotation of Chemical Structure Database

The goal of this project is to develop an automated system annotating chemical database, ChemReader for recognizing chemical structure diagrams in research articles and linking them with entries in the database. ChemReader system consists of mainly four steps: 1) Document segmentation building logical relationships of objects and elements in the input literature and natural language processing of text components to extract the contextual scientific knowledge, 2) Classification of chemical structure diagrams from documents objects or elements, 3) Recognition step converting classified chemical structure diagrams into standard, searchable chemical file formats, and 4) Annotation of chemical database entries which match to extracted structures of step 3) with obtained knowledge at the step 1). By annotating each molecule in the database with one or more relevant links to the scientific literature, the database would be a more useful resource to bio/chemical research scientists. ChemReader project has been worked in collaboration with Gus Rosania in College of Pharmacy, University of Michigan. Click here for a related ME news article.

Customer Driven Co-Design of Complex Products

In order to design innovative products, companies are involving customers in product design process through co-design. Co-design is changing the conventional design processes and replacing them with design processes that make customers an integral and active member of the design team. This co-operation between customers and companies has resulted in some very successful product designs. Nevertheless, co-design is still limited to very specific types of products. The research work will develop modified product design processes that are suitable for co-design and measure their success in innovative designs of complex products. This project is worked in collaboration with Prof. Richard Gonzalez in Department of Psychology.

Design for Crash Satety using Equivalent Mechanism Models

The goal of this project is to develop an efficient method for vehicle crashworthiness design based on a reduced-order model of vehicle structures, called “equivalent” mechanism (EM) model. An equivalent mechanism (EM) model is a network of rigid links with lumped masses connected by prismatic and revolute joints with nonlinear springs, which approximate aggregated behaviors of structural members during crush. An EM model of a vehicle is optimized by selecting the nonlinear springs among the ones realizable by thin-walled beams. The optimum EM model serves to identify a good crash mode (CM), the time history of collapse of the structural members, and to suggest the sizes of the structural members to attain it. After the optimization, the FE model of an entire structure is “assembled” from the suggested dimensions, which is further modified to attain the good CM identified by the optimum EM model.

Design for Disassembly with Heat Reversible Locator-Snap System

As recent legislative and social pressures drive manufacturers to consider effective part reuse and material recycling at the end of product life at the design stage, it becomes crucial to design and use joints that can disengage with minimum labor, part damage, and material contamination. This project presents a unified method to design high-stiffness reversible locator-snap system that can disengage non-destructively with localized heat. The problem is posed as an optimization problem to find the orientations, numbers, and locations of locators and snaps, and the number, locations and sizes of heating areas, which realize the release of snaps with minimum heating and maximum stiffness, while satisfying all motion and structural requirements.

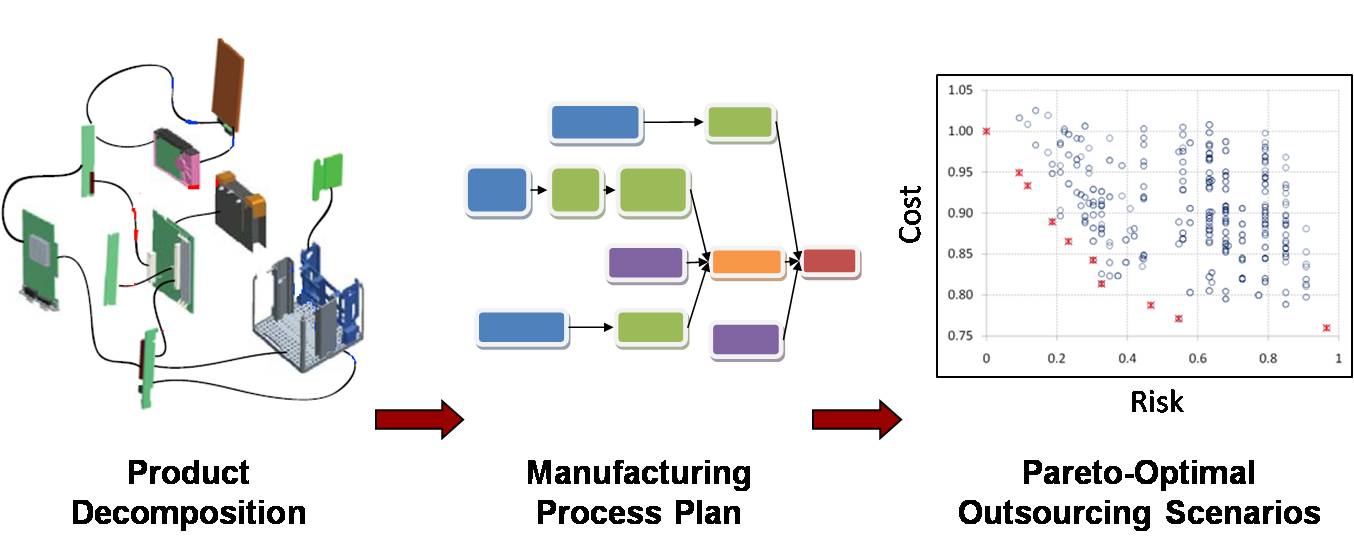

DFIP: Design for IP Protection

Component outsourcing is often practiced in today’s markets in order to reduce the overall cost of products and maximized profitability. However, when new innovative products are introduced into markets, there is the concern that outsourcing would cause the product’s details to be reviled, and ‘similar’ products finding their way into the market. This research aims at developing a framework for product functionality decomposition and selective outsourcing in order to protect the key competencies and intellectual property, while satisfying quality, cost and lead-time requirements.

Design for Product-Embedded Disassembly

Design for product-embedded disassembly is a new approach to Design for Disassembly that aims at designing products with built-in disassembly means to be activated at the end of product life. the relative motions of components are constrained by the locators (tabs, slots, lips, rests, etc) integral to the components, in such a way that the removal of one or few fasteners would cause the self-disintegration of the assembly in a unique sequence, much like the domino effect.

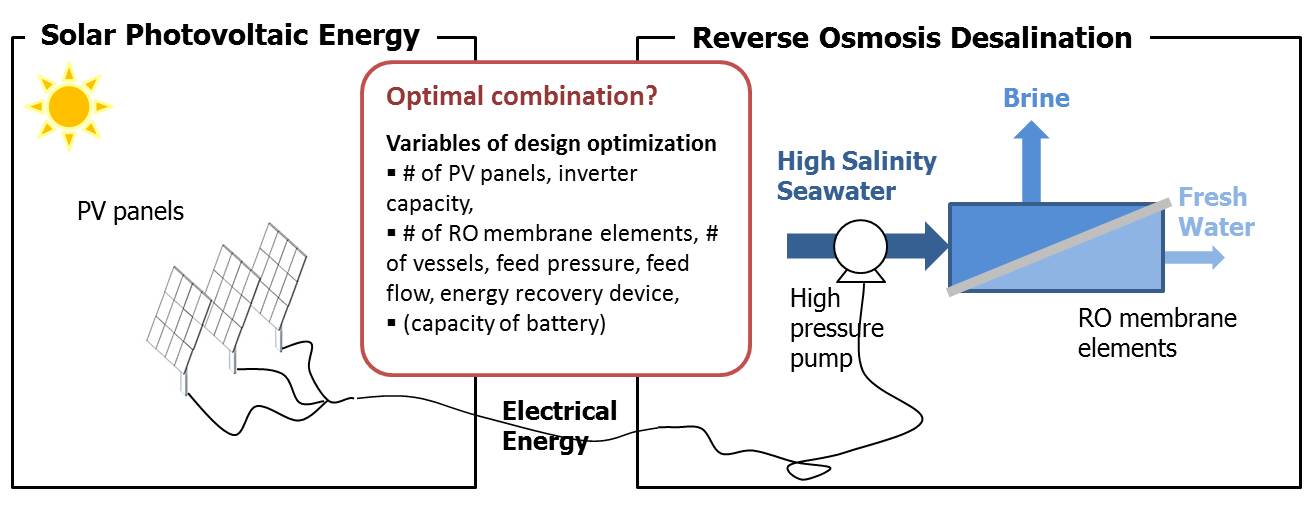

Design Optimization of Photovoltaic-Powered Reverse Osmosis Desalination Systems

Combining solar photovoltaic (PV) energy source and reverse osmosis (RO) desalination has been considered as one of the most promising water generating systems for remote areas where water source is scarce while solar irradiation is abundant. Due to the time-dependent nature of PV electrical power, this desalination system have been equipped with batteries in order for RO desalination system to continuously operate at constant feed pressure and feed flow. On the other hand, PV-RO systems have been designed without batteries since the use of batteries is associated with high capital cost. We are going to investigate on the design optimization of PV-RO desalination systems both without and with batteries, and compare the performances of the optimized systems. This work is in collaboration with Prof. Sayed Metwalli at Cairo U and Profs. El Morsi and Nassef at American U of Cario.

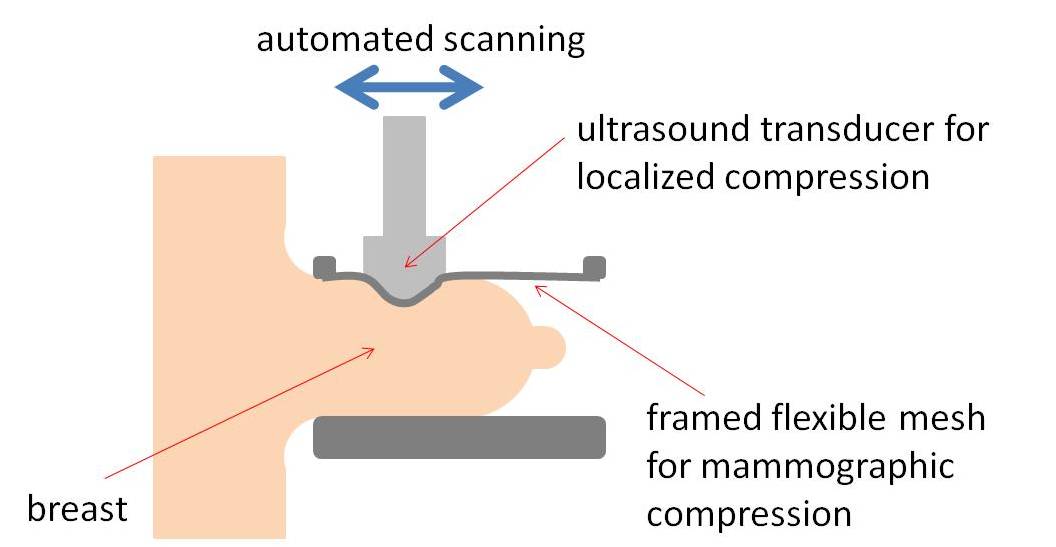

Locally-compressed automated ultrasound scanning system for breast cancer screening

Breast cancer is the second leading cause of cancer deaths in women today. About 1.3 million women are diagnosed annually worldwide and about 465,000 will die from the disease. Automated ultrasound (AUS) imaging is a very promising breast cancer screening technology that can detect cancers in dense breasts, particularly with extreme compounding. However, AUS has been less successful than expected since the ultrasound imaging is limited in resolution and contrast due to increased shadow artifacts from the tissues compared with what is achieved with hand control of the transducer array. Recent study has shown that this difficulty in AUS could be significantly reduced in very light mammographic compression by a flexible mesh in a frame, along with additional localized compression of the breast as the transducer is scanned in contact with the mesh and the breast. The project aims at designing, testing, and charactersizing the automated system for locally compressed ultrasound scanning capable of yielding images in the same geometry as conventional and 3D mammography. This project is worked in collaboration with Prof. Paul Carson in Department of Radiology in Medical School.

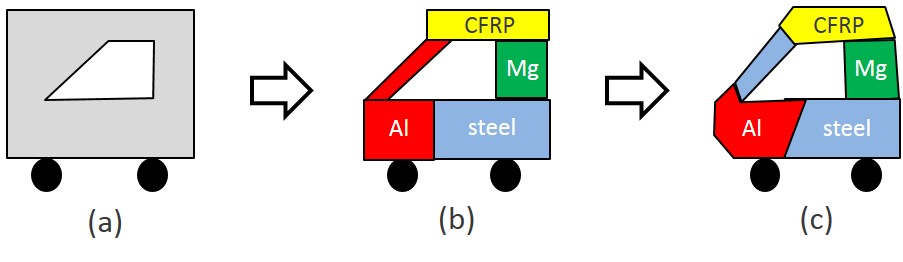

Multi-Material Topology Optimization of Vehicle Body Structures

The aim of this project is to develop a two-step method for multi-material topology optimization of vehicle body structures and demonstrating the developed method with a simplified body structure model of a mini-size electric vehicle. The first step ( (a)-(b) ) selects the overall structural topology and distribution of materials and plate thicknesses considering global bending and torsions, where the conventional SIMP method is extended to handle multiple materials and thicknesses. The second step ( (b)-(c) ) refines the selections of materials and thicknesses, and also joint configurations considering NVH and crashworthiness, where active learning based optimization is adopted to reduce computational time. The successful completion of the project will, for the first time, demonstrate the multi-material structural topology optimization of 3D structures with a complexity comparable to vehicle bodies. The developed method will contribute to the further weight reduction of vehicle body structures and to the improvement energy efficiency of future vehicles. This project is a part of US-China Clean Energy Reseach Center for Clean Vehicles (CERC-CV). Click here for a related ME news article.

Optimally Adaptive Product and Supply chain Systems under Severe Uncertainty

Currently, manufacturing enterprises in the high competitive global markets are vulnerable to uncertainties arising from disruptive events such as natural disasters, new technologies, or changes in environmental regulations. It is highly desirable to invest in resilience and flexibility so as to make a decision before the disruptions. The objective of the research is to enable a manufacturing enterprise to proactively adapt the product designs and the supply chains in anticipation of unplanned, but foreseeable high impact events, while still maintaining the competitive product quality, cost, and lead-time. This work is done in collaboration with Dr. Lalit Patil in Department of Mechanical Engineering.

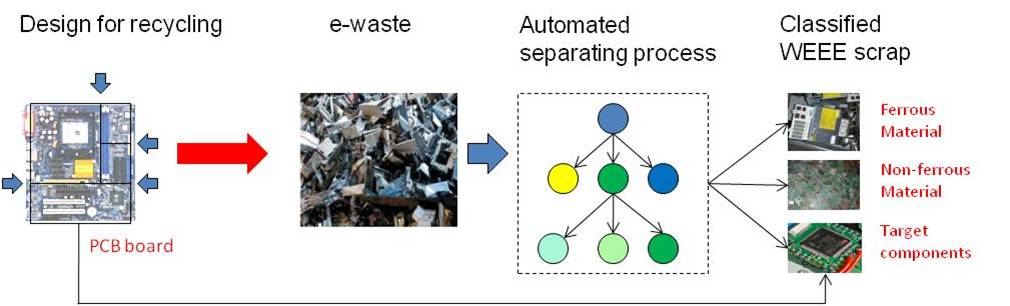

Product-Process Co-Design for Selective Material Separation in E-Waste

The project aims at developing a product design methodology to enable energy-efficient selective material separation in e-waste. Current separation processes rely on physical properties of materials such as density, magnetivity, and conductivity to separate recyclable materials in shredded e-waste. These processes are, however, often energy intensive, low-yield, and require pre-shredding manual disassembly due to inherent uncertainties in the particle separation processes. We will explore the concepts of design for distractive disassembly combined with hammer milling processes, in order to enable electrical and electronics products that facilitate efficient material recovery and the associated material separation systems for extracting target materials.

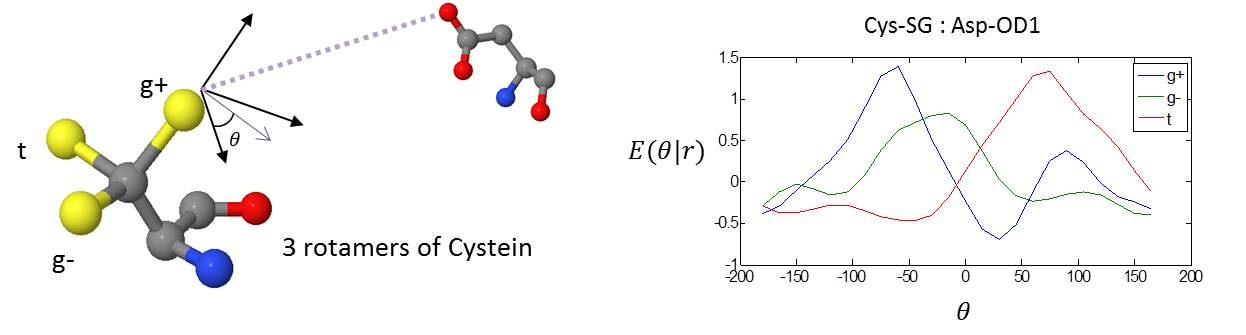

Rotamer-Dependent Atomic Statistical Potential for Assessment and Prediction of Protein Structures

Statistical potential energy functions are usually derived from known protein structures in the Protein Data Bank, and widely used in protein structure modeling and quality assessment. Since atomic interactions in protein structures can be more accurately described by multi-body potentials than typical distance-dependent energy potentials, it is desirable to take local environmental features such as secondary structure, solvent accessibility or side-chain orientation into account when developing potential energy functions. On the other hand, amino acid side-chains prefer to adopt only a limited number of conformations, known as rotamers. Thus, given a limited number of structures in PDB, the micro-environment of protein atoms can be effectively discretized by rotameric states of residues. Here, we have developed a novel rotamer-dependent statistical potential, which can improve the prediction accuracy of side-chain conformations as well as overall folded structures. Click here for a related ME news article.

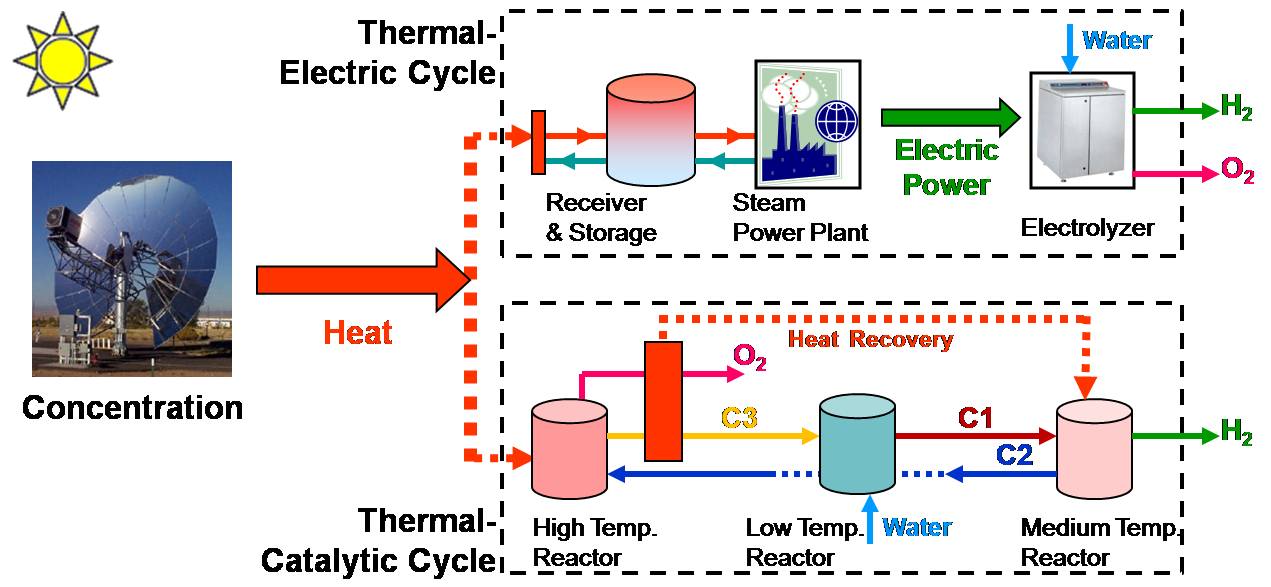

Solar Energy Concentrators for Hydrogen Production

Solar energy is a promising sustainable source for hydrogen production for fuel-cell vehicles. In most utility-scale applications, solar energy is concentrated as heat which, through an intermediate stage can be used to generate electric power that drives an electrolyses reaction to extract hydrogen from water. Alternatively, the heat energy can be directly utilized within a thermal-catalytic cycle. Solar powered hydrogen production is beset however by challenges in investment costs, power efficiency, variability in irradiance over daily and seasonal cycles, as well as maintenance costs. This project aims to develop hierarchal optimization models for system and device-level for the solar energy concentration, dispatch and usage, with the objective of overcoming many of the cost and efficiency challenges.

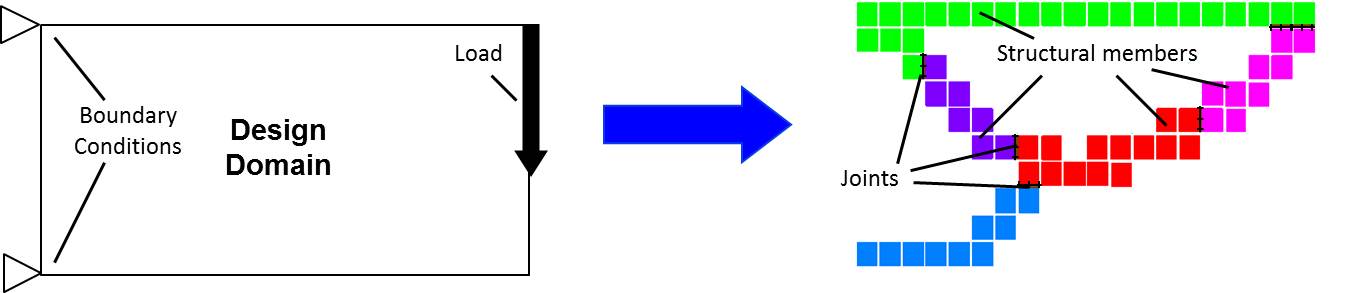

Top-Down Structural Assembly Synthesis

Topology optimization is the process of allocating structural material within a design domain (subject to certain loading and boundary conditions) in order to optimally achieve a desired functionality. An extension of topology optimization, this project aims to develop a top-down structural assembly synthesis. Unlike regular topology optimization, which generally deals with a monolithic structure, optimal assembly synthesis faces the unique challenge of coupled material allocation within a design domain, as well as allocation of separators (joints). It is established that the optimal material allocation depends on the joint allocations, and in turn, the optimal joints allocation depends on the material allocation , which means that to reach a global optimal, both problems must be solved simultaneously. This research also considers multi-objective performance measures of the synthesized structures such as structural performance (mass and stiffness), assemblability and manufacturability

University of Michigan Solar Car Team

Well, this is not exactly a research topic, but I was the Engineering Faculty Advisor for the University of Michigan Solar Car Team from 2008 to 2012. Our recent accomplishments include the 3rd place in 2009 World Solar Challenge and the 1st place in 2010 American Solar Challenge. Click here to learn more about the team's activities. Photo courtesy of UM Solar Car Team. Copyright The University of Michigan Solar Cart Team, all rights reserved.