New York Times , March 27, 2007

In the Lab: Robots That Slink and Squirm

By JOHN SCHWARTZ

MEDFORD , Mass. — The robot lies dissected on the black slab of a lab table, its silicone rubber exterior spread and flattened like a trophy snakeskin. Hair-thin wires run in a zigzag line along the inner length of its pale artificial flesh.

Barry Trimmer flicks a small switch and the wires contract, causing the silicone to bunch up; the skin crawls, so to speak.

So does mine.

“It's very organic,” Dr. Trimmer says with a smile. Apparently, “organic” is a technical euphemism for “creepy.” But it is eerily lifelike, and that is the point.

Robots, once the stuff of science fiction, are everywhere [emphasis added]. Robotic geologists are puttering around on Mars, little Roombas suck up dirt in the breakfast nook. But most robots are made up of hard components and don't much resemble the creatures that walk, crawl and squirm all around us.

At Tufts University , a multidisciplinary team of researchers wants to take a softer approach. The Biomimetic Technologies for Soft-bodied Robots project is trying to make an ersatz caterpillar that will move around in pretty much the same way as the real thing. The researchers see the potential to use the squishable, relatively simple creations to find land mines, repair machinery in hard-to-reach spots and even diagnose and treat diseases.

The project, part of a wave of interest in life-imitating robotics, is a collaboration of seven Tufts faculty members from five departments in the schools of engineering and arts and sciences. Dr. Trimmer comes from the field of neurobiology, where he has been studying the tobacco hornworm, Manduca sexta, since 1990. He has long been fascinated by the way that a seemingly simple creature like the hornworm (which, confusingly enough, is not a worm but a caterpillar) can twist its body in almost any direction and climb among the tree branches.

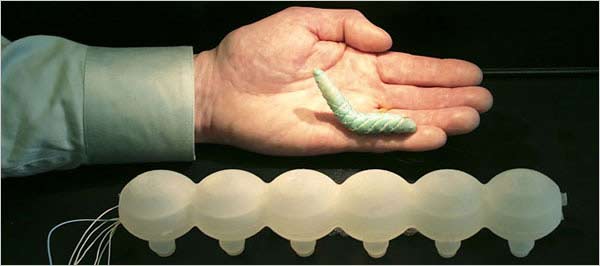

He pulls a box from his backpack and takes out one of the caterpillars, and puts it on the back of my hand; the caterpillar, oddly hairless and the greenish-blue color of classic Crest toothpaste, has a slightly raspy feeling to the grippers at the ends of its many legs. It rears up and twists to face backward. “How do you make a machine move with that kind of versatility and dexterity?” Dr. Trimmer asks.

The problem with motion and conventional robots is that hard joints don't just allow movement, and they restrict the range of motion. “Each joint adds exponential problems of control,” he says. The multiple-jointed arm of the space shuttle, for example, can take cameras, equipment and astronauts to an astonishing array of positions, but the process of planning every movement is enormously complex.

Yet, the Tufts researchers point out, a caterpillar needs no postgraduate training before it begins to slink across a leaf. Remove the hornworm's primitive brain, and it still trudges forward. So Dr. Trimmer suggests that much of the secret of locomotion is inherent in the muscles and the body. The hornworm has just 70 muscles per segment, with just one nerve controlling each muscle, for the most part. The researchers suspect that the wonderfully flexible locomotion of the caterpillar might emerge naturally from relatively simple rules.

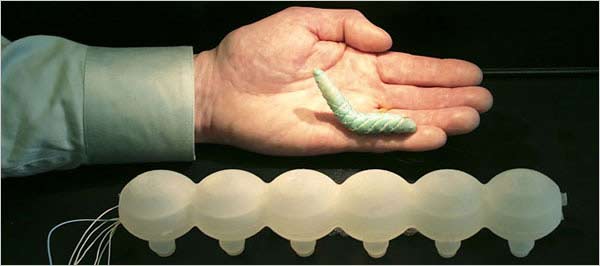

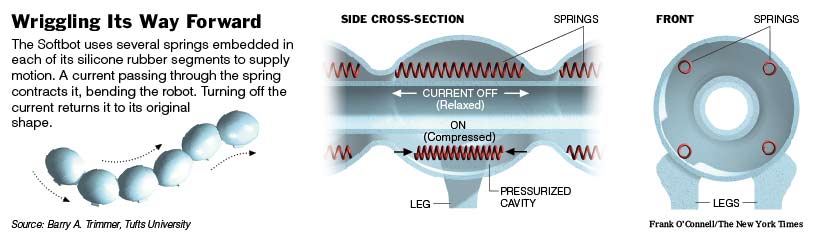

The researchers are seeking a similar elegance in their creations. The initial creatures are hollow tubes. The “muscles” are wire springs made from shape-memory alloy. Electrical current heats the springs, causing them to constrict; once the current stops, the elastic skin stretches the wire back into its resting shape. “It's almost childish, the simplicity of the design,” Dr. Trimmer says.

The skin is a silicone rubber that goes by the brand name Dragon Skin, and its composition can be manipulated so that it can be leathery-tough or so supple and clammy that it gives a sense of what it must be like to shake hands with Gollum. Eventually, the researchers hope to build on the work of David Kaplan, a Tufts professor of biomedical engineering who has pioneered the creation of tough, flexible materials based on spider silk so that the creatures would be largely biodegradable.

Aside from the dissected caterpillar on the table, there is just one other completed model, but it is inert, having pulled a muscle, as well as bits of squirmy this and that. The research, which is financed by the W. M. Keck Foundation, “is very preliminary,” Dr. Trimmer admits.

The researchers have gotten a wave to propagate across a robot's body; that wave picks up the feet in a way that already resembles the foot motion of a real caterpillar. By the end of the year, they hope to have robots capable of full locomotion that emulate the action of the caterpillars, he said. The puzzle of coming up with computer code to coordinate the movements, they suggest, will be greatly accelerated using the rapid trial-and-error approach that, in the world of computing, is called genetic algorithms.

They see a day when the cheaply built machines — less than a dollar apiece, Dr. Kaplan predicts — could be crammed into a canister and shot into a minefield. The hollow bodies would contain a simple power source and mine detectors; the caterpillars would wriggle across the terrain at random, stopping when they detect a likely mine. “There's no need for high speed,” Dr. Kaplan said. “Slow and steady is fine.”

The team suggests the caterpillars could similarly be used in hazardous, hard-to-reach spots in nuclear reactors and spacecraft. They also see a role in internal medicine as crawling probes and sensors, a prospect that patients might find difficult to accept, but which might eventually help doctors navigate some of the body's trickier passageways.

In trying to reproduce the caterpillar, the Tufts researchers are taking part in one of the biggest trends in robotics and locomotion studies, which are increasingly taking inspiration from the world of biology. Joseph Ayers of Northeastern University has created an artificial lobster. Ian Walker of Clemson University has a robotic arm that draws its inspiration from the elephant's trunk and the octopus's arm. There are robotic salamanders, snakes, cockroaches, fish and geckos.

“It's a hot topic,” said Auke Jan Ijspeert, head of the Biologically Inspired Robotics Group at the Swiss Federal Institute of Technology. He created the “salamandra robotica” as a way to prove theories about how a salamander makes its twisting course. “I'm basically amazed by nature,” he said, “and how impressive animals are at solving the problem of locomotion control.”

Dr. Ijspeert called the Tufts project “very exciting, very new.” At the same time, he pointed out, animal models can only go so far. He tells his students, “You should not aim at blindly imitating nature.”

Evolution, the engine of development, is brilliant but not necessarily efficient, he said. “The biological solution is always a little bit messy — it's based on previous systems,” he said. Working without precedent, he said with a touch of hubris, a researcher can shape a more elegant solution than nature has.

That blended approach helps to guide researchers at the Information Sciences Institute at the University of Southern California, where the “Superbot” can configure itself to squirm like a worm, crawl like a turtle, roll like a tire and more. Their work is financed in part by NASA , which wants robots for future missions that can get around in any number of ways. “Wheels are a marvelous invention, but they have their place,” said Peter Will, a U.S.C. researcher. Bicycling on sand is hard, he said, while walking on it is easy.

The U.S.C. institute has another layer of natural influence, said Wei-Min Shen, the director of the institute's polymorphic robotics laboratory: communication among robots that is inspired by hormones . “Because there's no fixed brain, we need a signal that will circulate within the system,” he said. Like Dr. Ijspeert, Dr. Shen says nature can be a bit limiting. When he has to get up to write on a whiteboard, he says, he thinks, “If I can reconfigure myself and take off my left arm and connect it to my right arm, I can do so without standing up or leaving my chair.”

Robotics researchers talk like that.

The road ahead could be far longer and more difficult than it seems today for the Tufts researchers, said Dr. Walker of Clemson. While expressing enthusiasm for the project, he cautioned that soft is hard. When he embarked on a project to create the flexible robotic arm more than five years ago, he had hoped to stick with soft materials. But “it's very hard to engineer with all-soft components,” he said. “We had to make compromises along the way” to get the strength and force that the arm needed.

There were other challenges. Designing computer programs to operate the arm was something “we thought we would spend six months working out,” he recalled. “Two or three Ph.D. theses later, we finally understood the problem. Not that we had solved the problem. We understood the problem.”

“So,” he said, “I'll be interested to see how closely, when all is said and done, the Tufts group are able to meet their goals.”

Dr. Trimmer said, “I've got a lot of confidence it will work.” And besides, he added, “If we don't make the exact robot that you and I are discussing, what have we got? What we've got is an entirely new approach to motion control.”