Heat Treating Titanium

Anodizing Titanium

Anodizing of titanium is exceptionally easy and is a totally different process from aluminum anodizing. Simply, you prepare a mild ionic solution, then you apply a controlled DC voltage to the titanium specimen (the titanium is on the positive terminal). A sheet of stainless steel (I used type 309 stainless foil) is used as an electrode in the bath, to which you connect the negative terminal of your power supply. It is good practice to make the foil electrode larger in surface area than the titanium specimen to be anodized.

You can stack batteries in series with

an adjustable voltage supply to achieve the necessary voltage for the color

you desire. Measure the actual voltage using a DC volt meter.

I used 12V motorcycle batteries in series with a 0-30VDC adjustable supply.

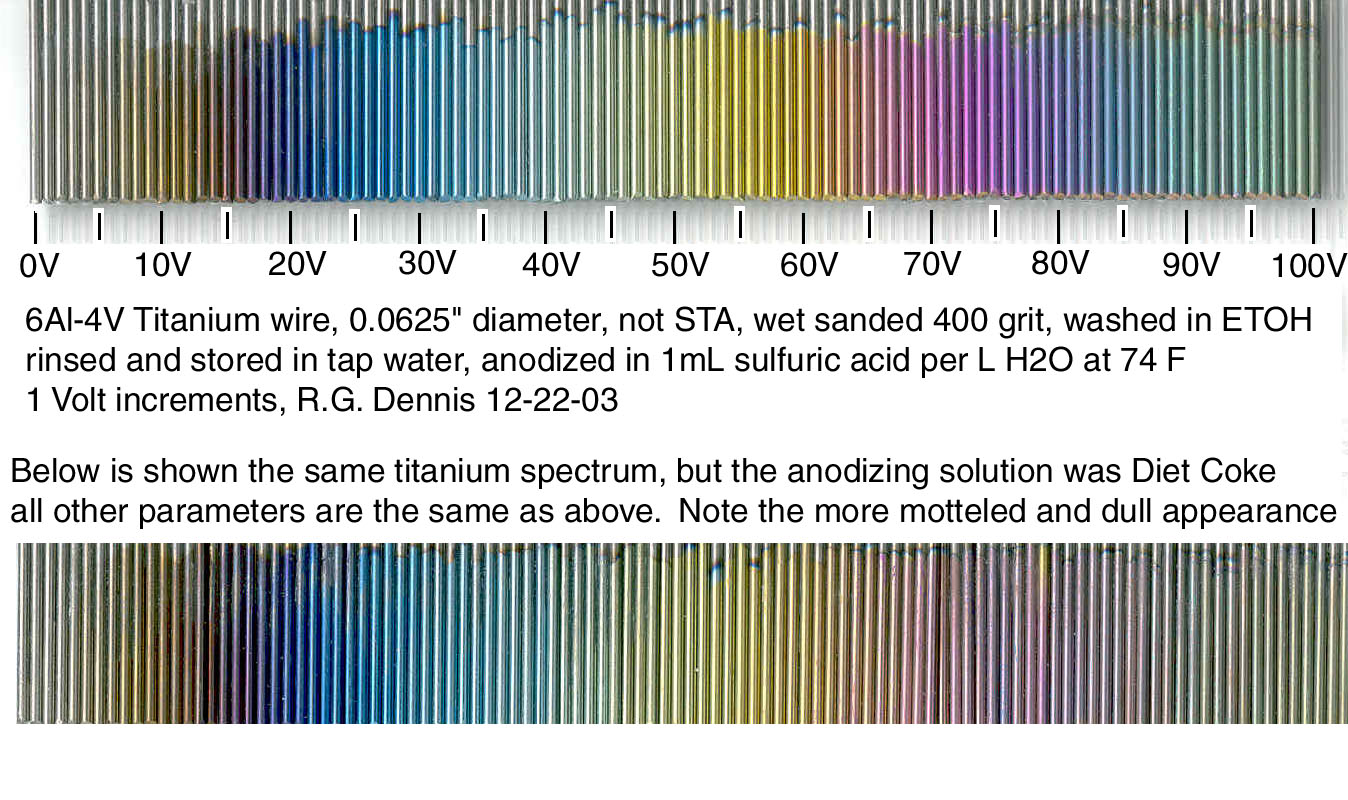

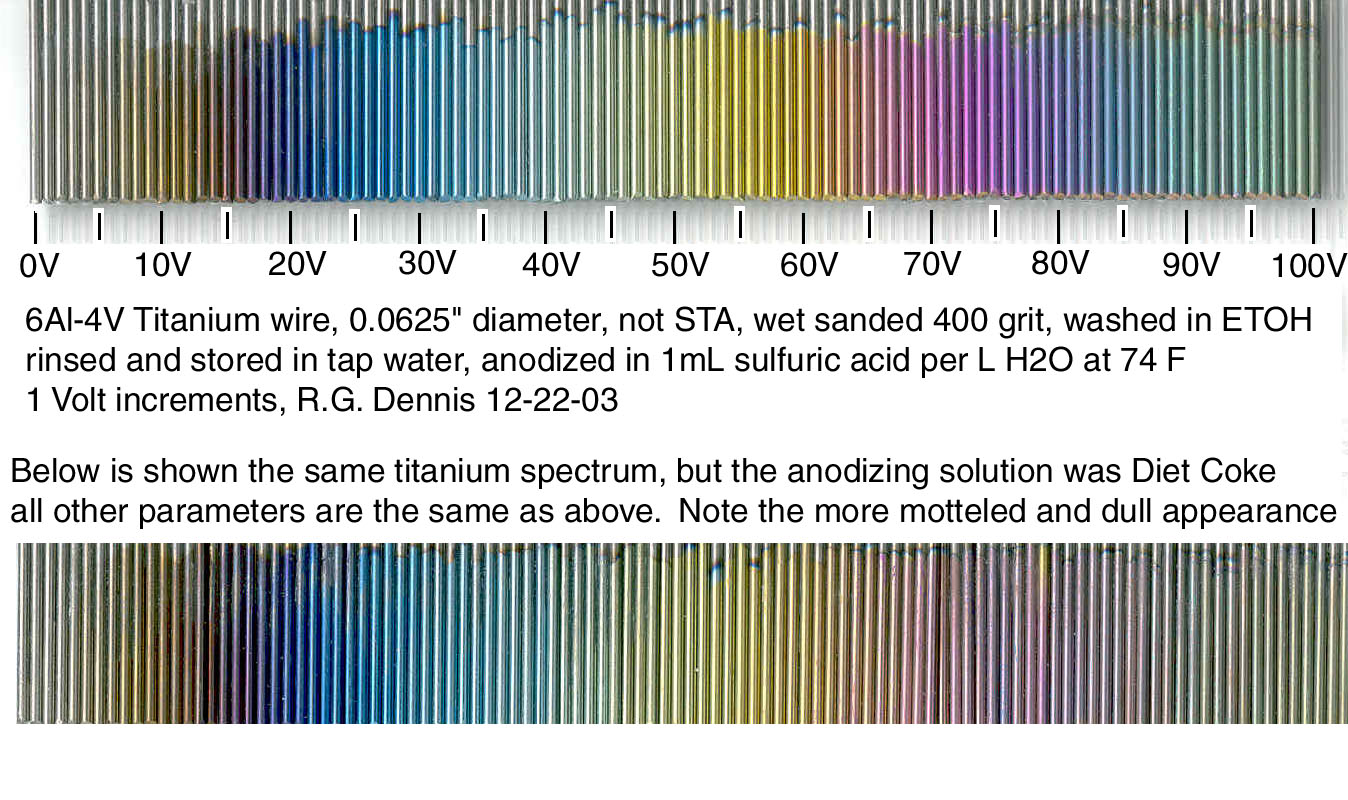

In the image below, each titanium wire specimen was clamped in a stainless-steel

alligator clip during the anodizing process, which is why the top of each

wire is not anodized. the entire process of anodizing takes only

a few seconds at most, and is easily visible. When finished, rinse

in tap water and you are done! No dyes or inks are required.

The surface has a color due to the optical properties and thickness of

the titanium oxide coating. The basic physics is similar to the color

spectrum in an oil slick on water.