|

Pitney-Bowes Paper Folding Machine: Mechanism Design Course: Kinematic Synthesis Instructor: Prof. Daniel Walczyk Duration: Spring 1999

|

|||

|

Objective The purpose of this exercise was to redesign the control settings of a Pitney Bowes Paper Folder Module: Model F402. In its current design the paper folder can make eight different kinds of folds, or allow paper to pass through it unfolded. It accomplishes this by using ‘fold rollers’ to move paper along ‘fold plates’. The three fold plates have ‘fold plate stops’ to control the length of the folds. Three ‘deflectors’ are used to control which of the three fold plates the paper can go into. In all there are six controls that have to set by a user before operating the machine.

|

|||

|

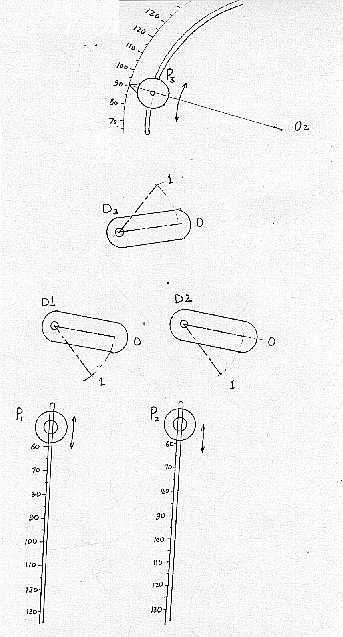

Project Discussion In the present control panel layout of the machine, the location and configuration of the manual fold-controls (D1, D2, D3, P1, P2 and P3) are as follows: |

|||

|

|

|

||

|

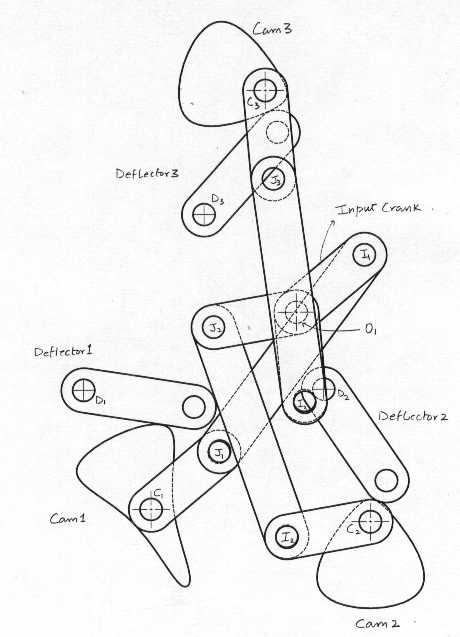

Proposed Mechanism Design A linkage mechanism is proposed, which if incorporated in the machine’s design, reduces the number of controls to be adjusted by the user. Three four-bar mechanisms with a common crank are used to set the deflector positions. Since the mechanism has one d.o.f, a single input is required to adjust these three controls. Furthermore, it is observed that for a standard size paper, two of the paper stop knobs can be semi-permanently fixed. The third one is actuated by means of a four-bar function generator. As in the previous case, this mechanism also requires a single input. The inputs to the above two mechanisms are made common so that there is only one input crank for the entire mechanism. Thus the overall mechanism has a single degree of freedom and requires only one setting for selecting a paper fold type. This single input is placed as a knob on the front panel. As is evident, the number of control inputs has been reduced from six to just one. The desired task is thus accomplished. A figure of the multi-loop mechanism is presented.

|

|||

|

|

|||

|

A limitation with this design is that it reduces the operational flexibility of the machine i.e. paper of only one standard size (11” x 8.5”) can be used and only four different folds can be made. But the advantage is significant. On similar lines further mechanisms can be developed to accommodate different size papers and more folds. The manually operated knob can be replaced by a servo-motor to actuate the mechanism.

Previous: Inverted Pendulum Systems Next: Boot-life Testing Mechanism

|

|||